This project explains how to repair a cracked frame and broken switch on a DeWALT® DC987 18V cordless drill driver with J-B WELD® epoxy while waiting for replacement parts to arrive.

I was working on the ladder when I dropped my DeWALT cordless drill about a dozen feet on the concrete floor. The motor and gears were undamaged, however the clamshell body was badly cracked and the internal switch lever snapped in two. Since I was in the middle of a job and really needed my cordless drill, I repaired the plastic case and switch level with J-B WELD epoxy so I could keep working. J-B WELD is ideal because it bonds almost anything, cures hard and can be filed, drilled and machined.

How to Repair a DeWALT Cordless Drill/Driver

The motor and gears still worked fine, but only in forward mode because the forward/reverse switch lever was broken and rattling around loose inside the drill body.

After removing the battery, I dissembled the DeWALT cordless drill by removing the torx screws from the end cap, gear box and handle to inspect the damage. The clamshell case cracked on both sides just above the trigger and the forward/reverse switch lever had broken off at the rear post as indicated by the red arrows.

J-B WELD® Epoxy Repair

I lightly buffed the inner and outer surfaces of the clamshell drill case with sandpaper to “break the shine” to create a better bonding surfacing for the epoxy. Do not sand inside the crack itself because the broken edges are a “new” surface that needs no additional preparation and you want to maintain the “jigsaw puzzle” mating surfaces.

J-B WELD was applied to the clamshell case and switch lever as indicated by the red arrows. The gear box was reattached to align and hold the clamshell case together in perfect alignment along with a bungee cord wrapped around the back of the case. A bar clamp is applied to hold the cracked case together while the J-B WELD cures.

The switch lever (blue line in the above photo) is an internal part that fits on top of the “Switch, V.S.R.” unit. I used a pair of needle nose pliers to bend up heavy copper tab on top of the copper heat sink so I could access the lever that fits over a rectangular post.

Being a major holiday all the stores were closed and I only had the 15 to 24 hour slow-cure J-B Weld on hand. If I were to do this again, I’d use the J-B QWIK® which sets in 4 minutes and fully cures in 4 hours.

DeWALT Cordless Drill/Driver Reassembly

Reassembly was straightforward, with two minor points:

- After installing the internal switch lever on the V.S.R. trigger switch, I put the V.S.R. switch in the

bench vise and slowly closed the vise to bend the copper tab back down over the lever. It took

some finesse to arrange the copper heat sink such that pressure is only applied to the

body of the heat sink while not contacting the plastic switch case; otherwise the plastic switch

would be crushed. - Turn the torque setting to the lowest value to relieve the pressure on the clutch plate before

reassembly, otherwise you’ll be fighting the spring pressure of the clutch as you try to

mate the gear box to the motor.

The drill is working fine again and the forward/reverse switch operates correctly. The clamshell case still has a gap above the trigger due to internal stresses from getting bent when I dropped it, however the gap is cosmetic and this is a short-term fix until my replacement parts arrive.

DeWALT Parts and Service

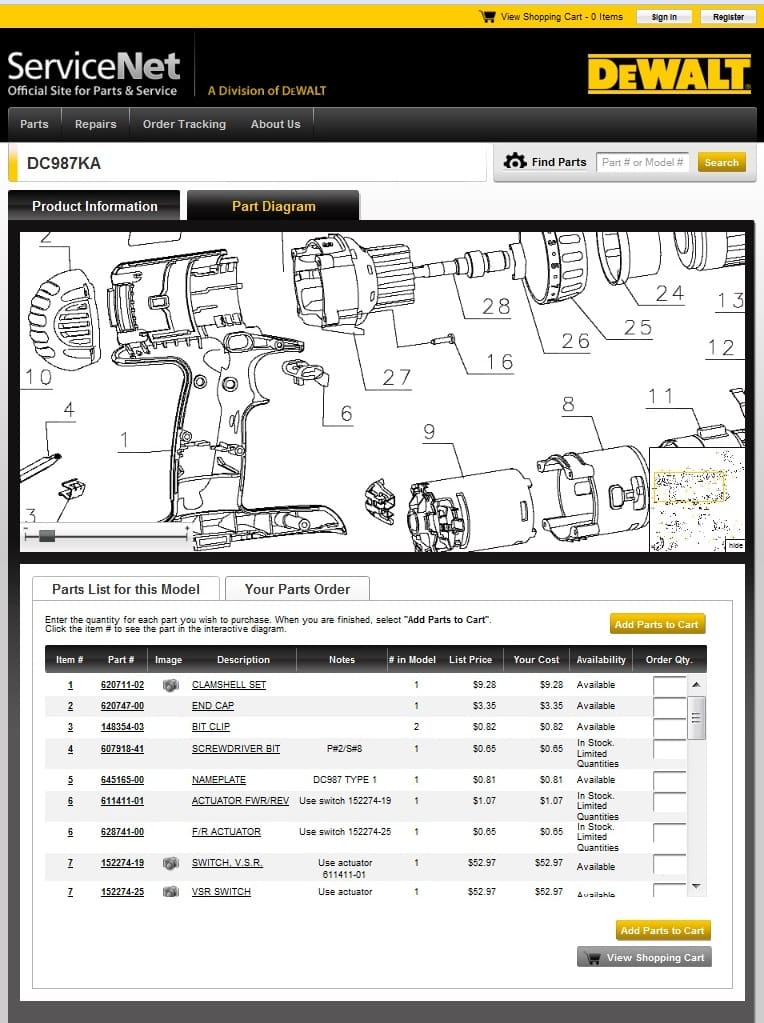

I surfed over to DeWALT ServiceNet® – “The official site for Parts and Service” to identify and order the replacement parts to make my DeWALT cordless drill almost as good as new.

DeWALT ServiceNet is user-friendly and after entering my model #: DC987, it’s a “Type 1” version – I was shown a detailed parts diagram, part list, photos and prices ready to order. I thought it interesting there were photos of the clamshell and switch – I’m guessing these parts get broken regularly as I had done.

I ordered the following replacement parts:

- “Clamshell Set”, Part # 620711-02 for $9.28

- “Switch, V.S.R.”, Part # 152274-19 for $52.97

I’m can also track my order status at DeWALT ServiceNet.

DeWALT Drill/Driver Clamshell Repair Part

The new clamshell set that I ordered for $9.87 from DeWALT ServiceNet® for the broken drill handle arrived. The new clamshell is identical to the original as expected. Replacing the clamshell only requires a torx bit to disassemble the drill.

DeWALT® Cordless Drill/Driver Disassembly

Taking apart my DeWALT DC987 cordless drill was easy:

- Turn the torque setting to the lowest value to relieve the pressure on the clutch plate.

- Remove the 4 torx screws from the gear case/keyless chuck unit. Point the drill downward and slide the gear case out of the clamshell, taking care not to let the clutch plate and gears fall out of the gear case.

- Remove the torx screws from the clamshell handle and end cap.

- Lift off the left half of the clamshell handle.

- Lift out the motor and switch assembly.

Layout the parts as shown to organize your work:

The design and minimal parts count is amazing when you think about.

DeWALT Cordless Drill/Driver Reassembly

Reassembly is just putting things back together in reverse order. The gear case/keyless chuck unit is the last part to be attached.

A slender torx screwdriver was necessary to reach the two screws set deeply in the bottom handle just above the battery.

Grease the DeWALT Cordless Drill/Driver Gears

The old grease was a bit dirty and some grease was lost on my fingers after two reassembly cycles. I wiped away the old grease on the motor face, clutch plate and gear case before applying a general purpose lithium gear grease.

I used a screwdriver to dip the grease from the cartridge and packed the gears with my fingertip. Here’s the new grease applied to the DeWALT gears:

After greasing the gears, reattach the gear case to the clamshell handle with the 4 torx long screws.

DeWALT Bit Clip Holder

The new clamshell didn’t include the bit clip, but it’s easy to install the clip on the new handle.

The metal bit clip has two retaining “wings” that hold it in the handle. Remove the bit clip by pressing the tip of a small screwdriver against the wing to release it, the clip will pop out.

Snap the bit clip into the new handle by pressing it in with your finger tip until it clicks in place:

DeWALT Cordless Drill/Driver Label

I forgot to order new DeWALT labels for the clamshell – these are available on DeWALT ServiceNet® for less than $1.

The drill is good as new, looks new, runs great and the repair parts cost me less than $10 plus shipping. Now I can spend the money I saved on new tools that I don’t have!

Take care,

Bob Jackson