How to Repair a Leaky PVC Pipe Joint by sawing out the bad pipe elbow and install a Fernco Qwik Ell flexible rubber fitting with band clamps.

I noticed another water stain on the finished basement ceiling – this time it was a leak in the washing machine PVC drain line. Two leaks on different sides of the room in the same month! Go figure!

How to Repair a Leaky PVC Pipe Joint

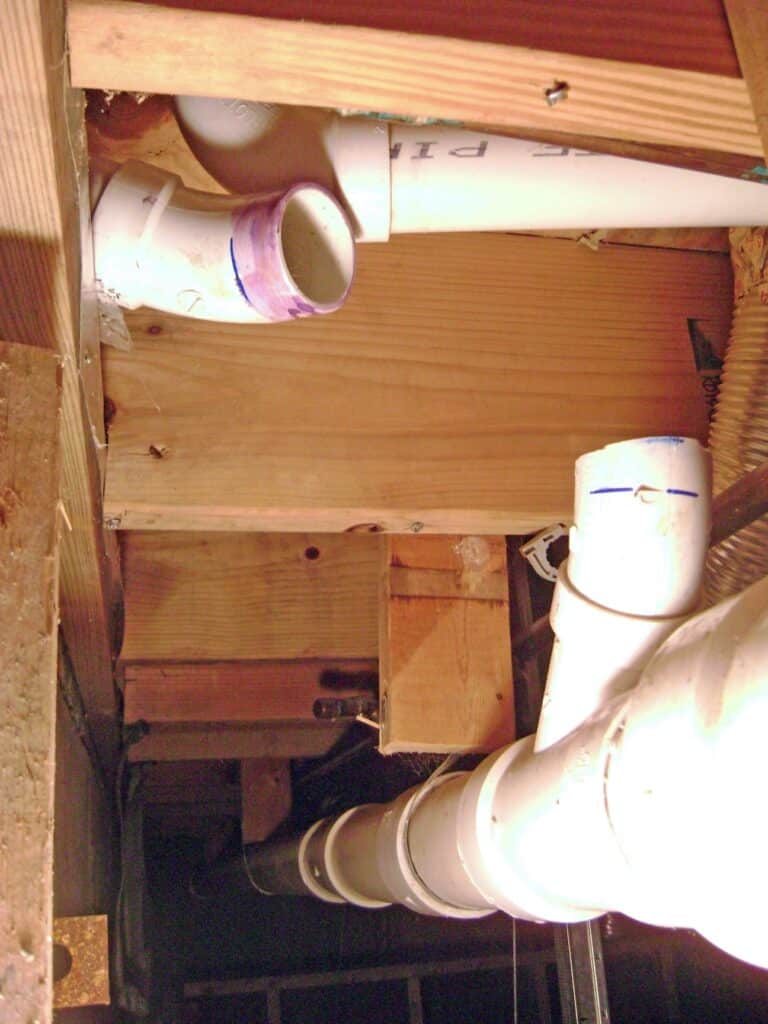

I was able to get access to the ceiling crawlspace by setting up a ladder in the closet. Access was awkward, but I was able to reach the pipe with an outstretched arm. I quickly found the leak, a slow drip at the PVC elbow joint in the washing machine drain. The solvent weld joint had partially failed, most likely because of poor workmanship as I was to about discover.

The finished basement has a suspended drywall ceiling. The next photo is the water damage to the drywall ceiling as seen from the crawlspace. I don’t frequent this room in the basement that often, but the leak couldn’t have been happening for more than a month.

Fernco Extra Length Qwik Ell Repair Fitting

The 2-inch PVC drain line is solvent welded (permanently glued) together. The correct way to make the repair is to cut out the bad section pipe and/or joints.

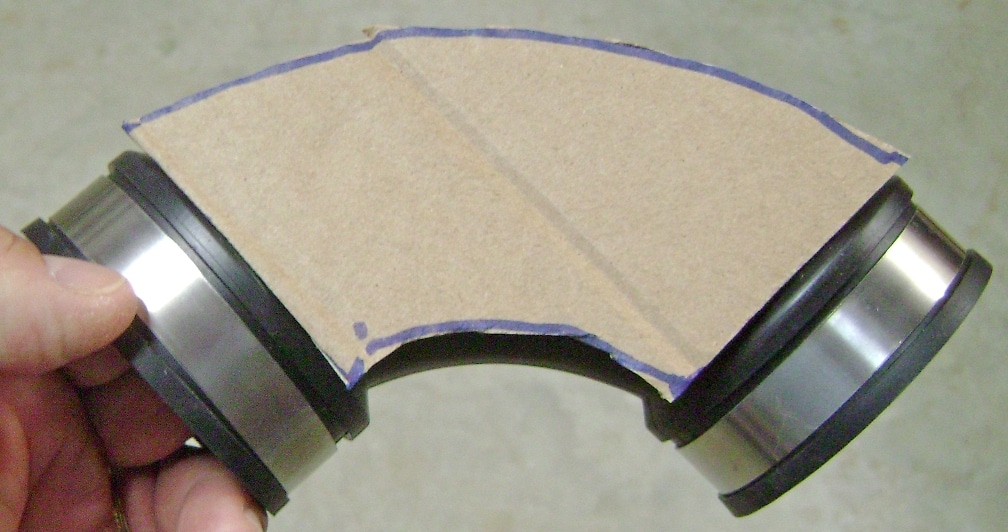

I purchased a Fernco 2″ inch QL-200 Qwik Ell at Home Depot to replace the PVC elbow. The Fernco Qwik Ell “extra length fittings” are perfect for the job. The “extra length” is necessary because the flanges of the PVC pipe elbow will be cut out, leaving a larger span than normal. The Fernco fitting accounts for the extra gap as shown here compared to a standard 90° PVC elbow.

Another view of the Fernco QL-200 with a vernier caliper that I used to measure the part:

Cutting out a section of PVC pipe is a significant decision because you only get once chance to make the proper cuts. I used calipers to measure the diameter of the 45 degree PVC elbow just below the glue joint where I’d be cutting the pipe because I wanted to reassure myself the Fernco Qwik Ell would fit. You won’t need to measure the pipe if you purchase the correct diameter Fernco Qwik Ell as this was for my edification.

I compared the diameter of the PVC pipe joint with the inside diameter of the Fernco Qwik Ell to confirm the fitting matched the PVC elbow. No surprise – if matched almost perfectly, just a bit on the small side as it should be for a tight fit. I just wanted to be extra sure.

Make a Cardboard Template

To mark the positions of the cuts on the leaking PVC pipe, I traced the outline of the Fernco fitting on a piece of cardboard. I needed to do this because there was no space between the PVC drain pipe and the floor joist to position the Fernco fitting directly to mark my cuts on the PVC pipe.

This is the cardboard template compared to the Fernco Qwik Ell. The important dimension are the lines marking the position of the shoulders at each end:

The template is cut along the lines to match the length of the shoulders:

Mark the PVC Pipe Cuts

The cardboard template made for the Fernco Qwik Ell is centered over the PVC elbow joint and the end positions for the cuts are marked with a blue marker (red arrows).

The section around the 90 degree elbow to be cut out is marked. You can see how the Fernco Qwik Ell will span the original PVC elbow joints:

Saw Out the Old PVC Pipe Elbow

After double and triple checking my measurements I used a carpenter’s handsaw to make the first cut below the PVC elbow. The handsaw cuts PVC like butter with a nice straight cut:

PVC Pipe Cable Saw

There was no room to maneuver the carpenters saw to make 2nd cut because the PVC pipe was against the drain line for the utility basin and the hot & cold copper pipes were immediately above. I purchased a Brasscraft PVC Cable Saw which requires almost zero clearance to operate.

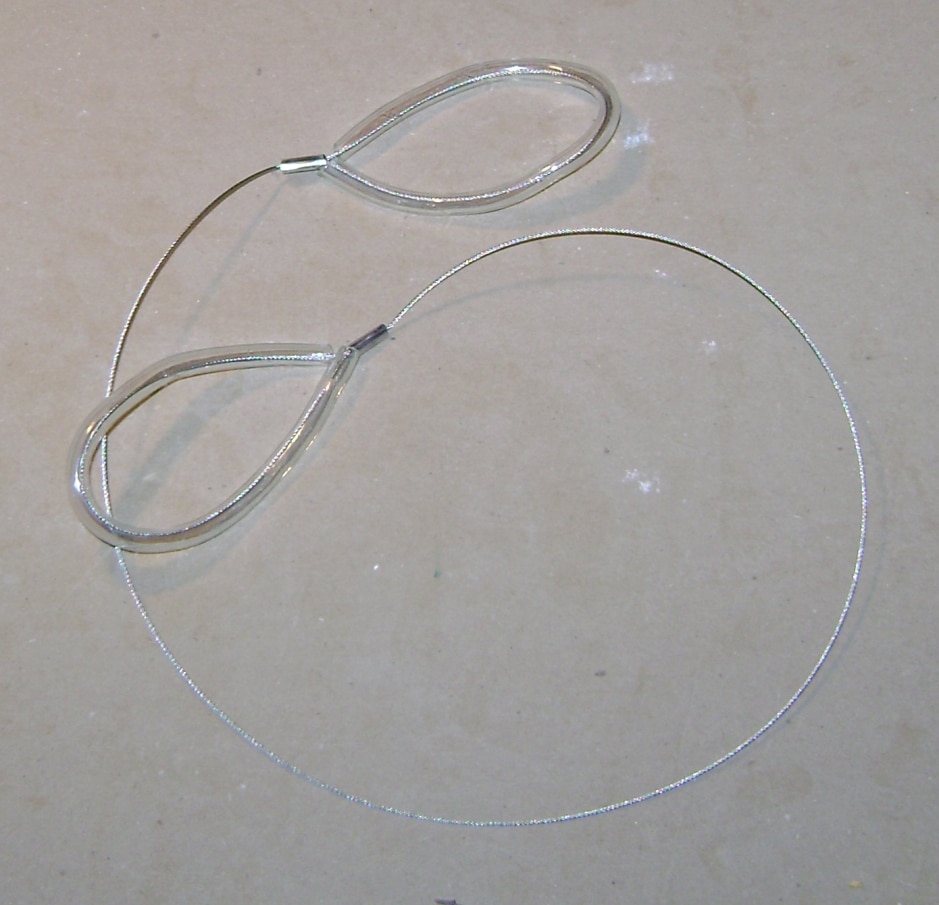

The PVC cable saw is roughed section of wire between two handles:

To make the cut, the PVC cable saw is looped over the pipe and pulled back-and-forth. I had never used one before and was a bit skeptical. It worked fast and easy!

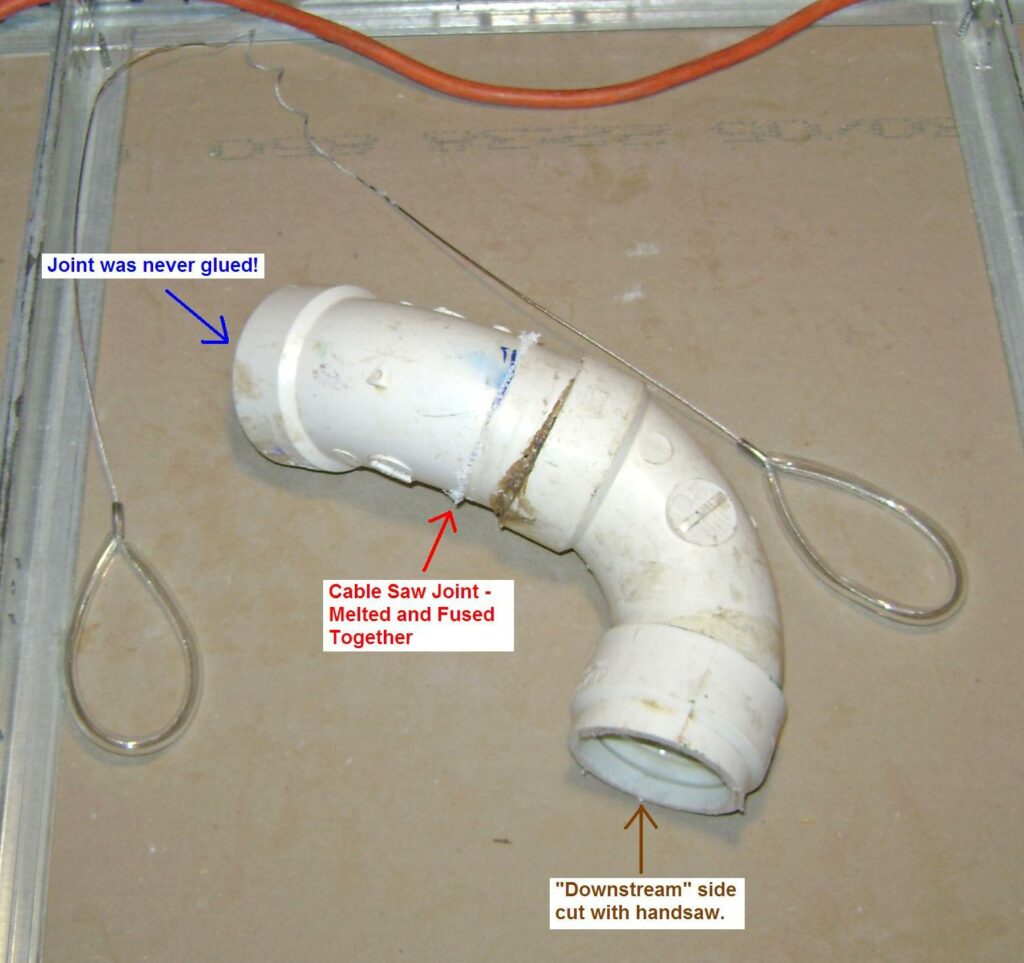

The PVC cable saw instructions warned the wire would get hot. It heated up so much from the sawing friction that it literally melted it’s way through the pipe section – and the pipe semi-fused back together as the wire cut through. I’ve since used the cable saw on other repair jobs and learned to work the cable saw more slowly if it’s melting rather than sawing through the pipe to reduce heating.

As I wiggled the pipe section to separate the saw joint, the 45 degree street elbow popped off! Upon closer inspection, I found the joint was never glued!! It was simply pressed together and luckily hadn’t leaked until recently:

Install a Fernco Qwik Ell Repair Fitting

In retrospect it’s only necessary to make the cuts against both sides of the 90° elbow joint. No measuring, no cardboard templates and no fuss. The Fernco Qwik Ell is made longer than a the standard PVC elbow to span the gap for just this type of repair:

Install the New PVC Pipe Joint

Now that the old leaky section of pipe is removed, I dried and cleaned the 45 degree street elbow on the “upstream” side as shown. I also deburred and cleaned the lower section of pipe that was cut with the handsaw. As you can see from this photo, the 45 degree elbow joint was never glued – a result of poor workmanship!

Test Fitting Fernco Qwik Ell

Next, I test fitted the two repair parts and marked the ends with a blue pen. The repair parts are:

- A new 45 degree PVC street elbow.

- The Fernco QL-200 Qwik Ell

The pieces went together perfectly.

I removed the Fernco Qwik Ell and checked my the depth of the blue pen marks to ensure the Ell was seated properly.

The replacement 45 degree street elbow was removed, the depth of the blue mark checked for proper seating and purple primer applied.

The new street elbow is solvent welded in place with PVC cement.

The Fernco Qwik is slipped onto the pipe ends and checked for proper seating at the two blue marks. The Quik Ell fitting is flexible and easy to work into place.

Do not use glue on the Fernco fitting. The Qwik Ell is held in place by the two steel band clamps and can be removed later if needed by loosing the clamps.

The steel band clamps are tightened with a socket wrench. I tighten it up until it’s firm, then take it in another 3/16 inch or so it squeezes the rubber fitting.

And the job is done! My wife was eager to run a load of clothes through the washing machine and the repair was leak free.

The last task is to paint over the stain on the drywall ceiling.

Leaky PVC Pipe Joint Inspection

A close inspection of the leaky section of PVC pipe that was removed was interesting. The “downstream” end is on the left, the leak is the stained section in the middle and the fused cable saw cut is the ragged section to the middle right.

This is the “upstream” end that wasn’t glued – but it hadn’t leaked here. An example of poor workmanship. This actually was a benefit in making the repair because the section popped off cleanly making the cable saw cut unncessary – but I didn’t know this at the time.

A smack or two cracked open the cut made by the PVC cable saw. The saw wire was so hot from friction it semi-melted it’s way through the pipe – the pipe tended to fuse back together behind the wire. Next time I would draw the cable saw back-and-forth more slowly to minimize the heat generation.

Hope this saves you some money on repairs!

Take care,

Bob Jackson