This project explains how to repair a rotted door bottom and weatherstrip.

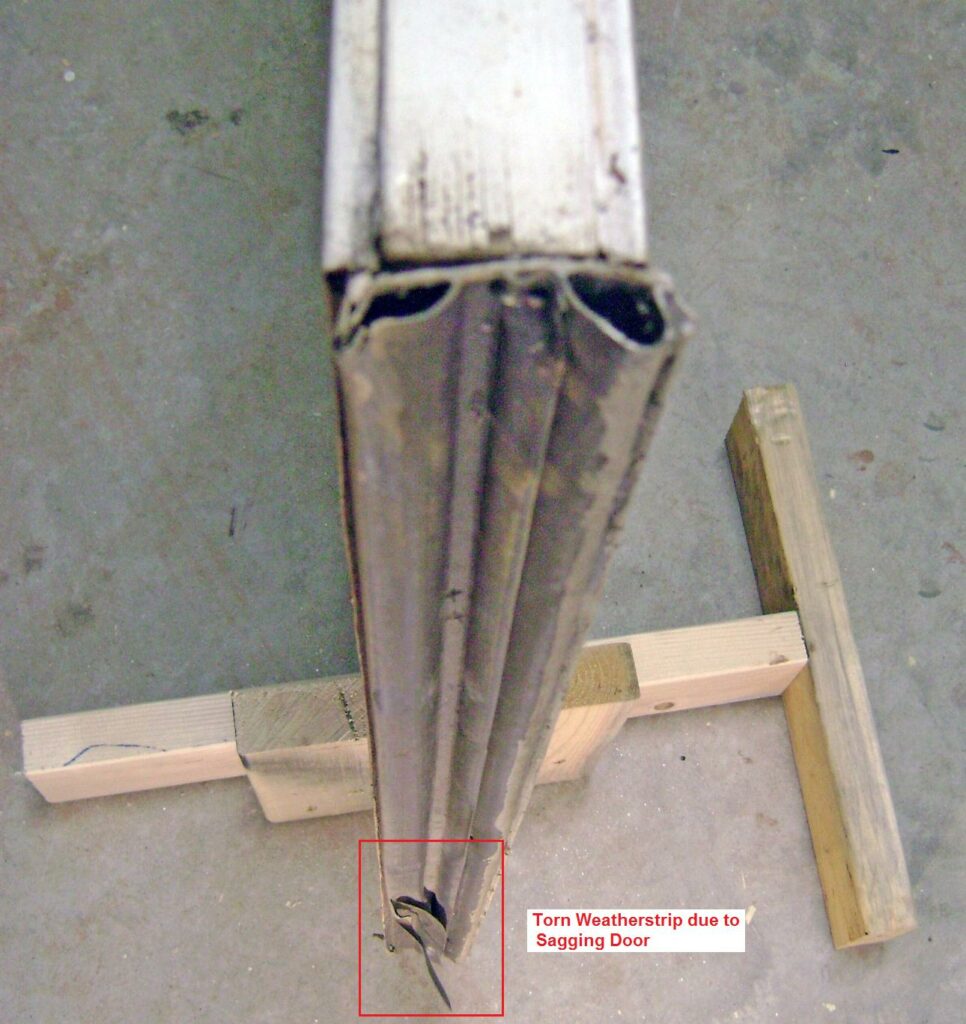

The single light French Doors at the basement patio are both sagging, resulting in a torn weatherstrip on the active door and a significant gap between the doors near the center bottom. The doors are sagging because each door weighs 65 lbs. and is a too heavy for the standard grade residential door hinges.

The patio doors are made of metal skins folded over an outer wood frame with a foam core. When I removed the door to replace the hinges and weatherstrip, I discovered the door bottom wood frame had dry rotted and was nearly gone!

Door Repair Jig

In anticipation of replacing the hinges on both doors, I made a jig out of scrap 2×4 lumber and 3 inch wood screws to hold the doors. French doors are expensive and I didn’t want to take a chance on breaking the glass panes.

My doors are 1-3/4 inches thick. Therefore the vertical 2×4 blocks are spaced 2-1/4 inches apart to form a slot about 6 inches deep to hold the door. Wedges are used to take up the slack. The other jig dimensions are not critical, but sized such that the can’t tip over. I found these to be rock solid.

If you’re worried about scarring the door faces, just lay an old towel inside the jig to protect door finish.

How to Repair a Rotted Door Bottom and Weatherstrip

This is bottom of the French door before I removed the old weatherstrip. I thought it would be simple repair to remove the old weatherstrip and install a new one. Little did I know the “fun” was just about to begin!

When I pulled off the old weatherstrip I discovered that most of the outer wood frame had rotted away. I scraped out chunks of what was left of the old wood. My first thought was termites but the side frames were solid and untouched. I saw no evidence of termite tunnels and the door jamb was also OK. Closer inspection revealed the tendrils and spider-veins of fungi due to dry rot.

The basement patio doors are shaded by the wood deck which created a cool moist environment that promoted fungi. Surprisingly the fungi only ate the bottom section and didn’t attack the side frames. My guess is the side frames are made of a different species of wood to take stresses of the door hinges and locks; or perhaps the door bottom was wet from splashing rain.

Here’s a closeup of the rotted wood. The bright area near the bottom left is the exposed foam core. I gave the inside a good spraying with bleach and water to kill any spores.

It was necessary to unbend the folded edge of the metal door skin to insert a new piece of wood. A pair of duck-billed sheet metal pliers (hand seamer) would have been ideal for the job. A large adjustable wrench did the job just as well, if more slowly. To minimize metal fatigue, I first bent the edge out 45 degrees along the entire length, then made a second pass to straighten it out flat as shown here. The lips on both sides was unfolded this way.

The dimensions of the replacement frame section is 1-11/16 inches wide by 3/4 inches thick by 31 inches long. The closest thing I could find was a 1 in x 4 in x 8 ft pressure treated board at Home Depot. Pressure treated wood resists rot and the outdoors. A nominal 1 inch board is actually 3/4 inches thick. To get a 1-11/16 inch wide board, I asked the Home Depot guy to rip it for me on the plywood saw because I don’t have a table saw. (Of course, you still buy the whole board, which is fine.) It was then a simple job to hand saw a 31 inch length when I got home. The new board fits in between the two end frames as shown in a notch that not too apparent in this photo.

The bottom of the door frame is filled with GREAT STUFF expanding foam insulation. GREAT STUFF expands to several times it’s initial volume and is very sticky. This will fill in all the voids in the door bottom and press the new wood frame tightly against the metal door edge.

The new pressure treated wood section is pressed into the door bottom. The GREAT STUFF is expanding and trying to push it back out:

I used a rubber mallet to bend the lip of the metal door skin over the new section wood. The outer corners of the wood strip acted as a sheet metal brake to accurately bend the metal just like the original construction. The GREAT STUFF is expanding and squeezing out nicely. This will hold the wood tightly against the door skin.

Larger view of the new wood frame in the door bottom. The GREAT STUFF at the red arrows completely filled the end gaps and is trimmed flush with the bottom.

Install the New Door Bottom Weatherstrip

The old weatherstrip attached by two ribs that fit into matching kerfs, or slots, in the door bottom. The new door bottom lacked these slots so I used a U-Shaped B79/36H Vinyl weatherstrip by Frost King. It attaches to the outside of a metal door with screws.

The weatherstrip is tested fitted on the door and marked to cut the length to fit the door. The installation was simple – test fit, mark the length, cut, test fit again, mark the screw locations, drill pilot holes and attach with screws.

End view of the U-shaped weatherstrip showing how it slides over the door bottom.

This is the new U-shaped weatherstrip installed on the door.

The new weatherstrip sealed well against the door sill, but a couple of things bothered me:

- The screws might rust.

- Water could seep in along the top of the weatherstrip and pool along the door bottom.

- The appearance didn’t match the other door.

I recommend caulking the screw heads and the top edge of the weatherstrip to seal out moisture.

I decided that I didn’t like the appearance of the U-shaped weatherstrip, so I removed door and cut slots in the wood door bottom to install the original kerf-mount weatherstrip as described in Part 2 of this project.

Thanks for reading,

Bob Jackson