The old deck rail is torn off and rebuilt to the current deck code requirements per the Georgia Amendments Prescriptive Deck Details based on the 2012 International Residential Code for a safer deck.

This project is continued from How to Drill Accurate Holes for Deck Post Bolts. Also see the project introduction at How to Repair a Sagging Wood Deck.

The house was built in 2000 and the deck rail predates the current deck code construction requirements. Two 4×4 guard posts were removed to fix the sagging deck and I needed to make repairs, so I decided to tear off the old deck rail in sections and build a new rail in compliance the deck building code with a nicer looking 2×6 rail cap.

4×4 Guard Posts

I bought 8 foot long #1 grade pressure-treated Southern Yellow Pine 4×4 posts from a local lumber yard. The minimum height from the deck boards to top of the guardrail is 36 inches per the Georgia deck code (see Figure 27 on page 15). The existing deck rail is 37-1/2 inches high so I was able to install the guard posts before tearing off the rail cap and pickets.

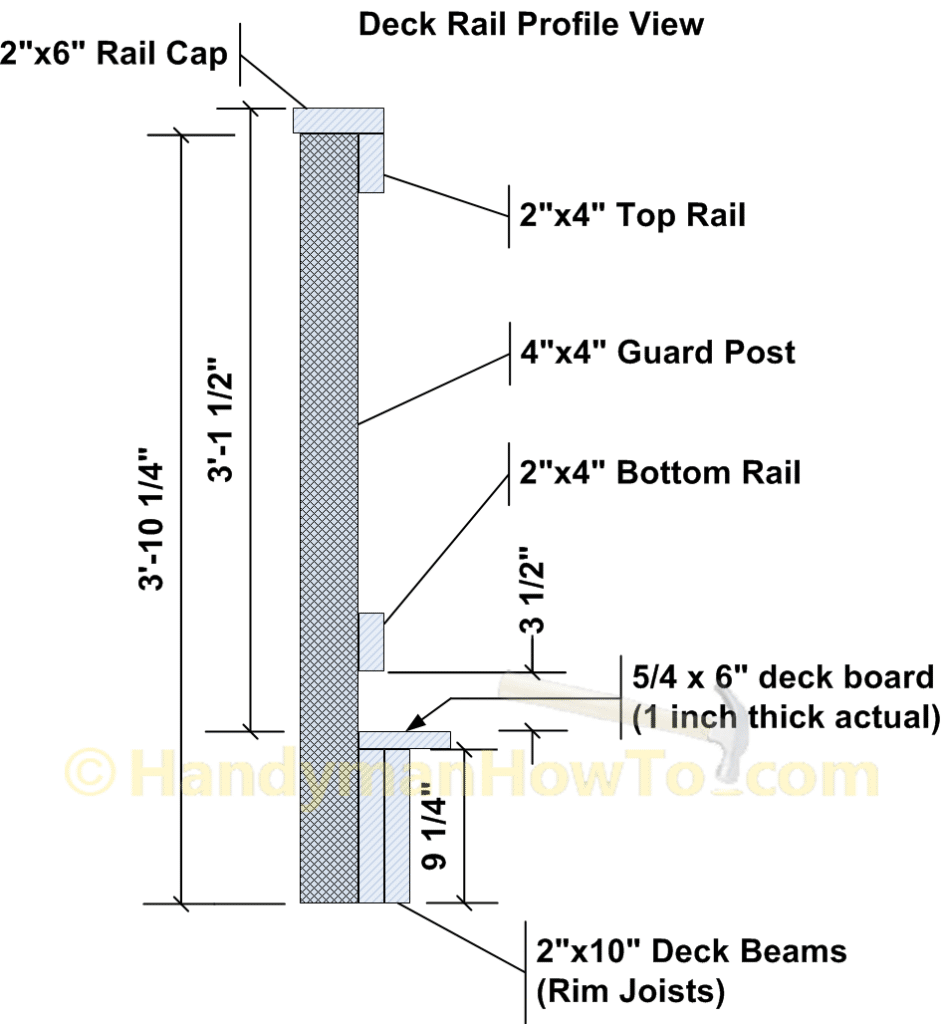

I measured and sawed 46-1/4 inch long guard posts that ran from the bottom edge of the 2×10 beams to the rail cap. This gave me two 4×4 guard posts per 8 foot piece of lumber with scrap. The measurements are explained in this deck rail profile drawing:

Deck Beam vs Rim Joist terminology: My deck was built using 2×10 lumber for the deck beams that also serve as rim joists. Deck beams and rim joists are two different framing elements in the deck building code (see Figures 2 & 3 on page 4) although the 4×4 guard post attachment with bolts and Simpson deck tension tie connectors is the same.

The guard posts were cut with my DEWALT compound miter saw then I measured and marked the positions for the 1/2 inch bolts with a combination square. Two holes are drilled using the Wolfcraft Drill Guide with a wood spade bit. See Figure 29 “Guard Post Attachment Detail” on page 15 the deck building code link (above) for guard post bolt placement requirements.

The drill guide made straight holes through the post which I couldn’t do freehand.

Install Code-Compliant 4×4 Guard Posts

The guard posts will be fastened to the deck with 1/2 inch galvanized bolts with washers and nuts spaced not more than 6 feet apart. Simpson Strong-Tie DTT2Z deck tension ties (“hold down anchors”) are installed so the post and rail will resist a 200lb load per Figures 30 and 31 on page 16 of the Georgia Prescriptive Deck Code.

The tools and materials needed to install the guard post are:

- 1/2 inch galvanized bolts with washers and nuts.

I’m using 10 inch long bolts although 8 inch bolts would be long enough. - Tape measure, hammer, spirit level, clamp (to hold the post against the beam so it doesn’t move while drilling through the beam)

- Copper-Green Brown Wood Preservative

- Simpson Strong-Tie DTT2Z deck tension ties

- Socket and adjustable wrenches

- Hammer for removing pickets and nails

Install Wood Deck Guard Posts

I’m working alone and needed three hands to install the guard posts. I solved the problem by fastening 1×2 support braces with Simpson Strong-Tie SD #9 x 1-1/2 inch screws to hold the guard post in place until I installed the 1/2 inch bolts (see next photo). The lower 1×2 block holds the guard post at the required height and bears the weight of the post on the 2×10 beam. The upper 1×2 strip is fastened with a single screw so I can rotate it vertically to slip it between the pickets, then turn it horizontally so it rests against the pickets to keep the post from falling outward. This system worked great!

The deck board was removed to better align the guard post and install the bolts and hold down anchor. I going to replace the decking, so it’s no loss.

Install Simpson Strong-Tie DTT2Z Deck Tension Ties

The 4×4 guard post is carefully positioned so the predrilled holes will be aligned with the Simpson DTT2Z deck tension tie, the post checked with the level and clamped to the 2×10 deck beam so it doesn’t slip. I drilled the 1/2 inch holes through the 2×10 beam with an extra long drill bit using predrilled post holes as a guide. The 1/2 inch bolts are installed with the DTT2Z post hold down anchor. I used a socket wrench to drive the SDS 1/4 in x 1-1/2 inch structural screws included with the DTT2Z in the joist. Tip: Tap the screw point into the joist with a hammer so the threads will bite.

The deck joists were originally toe-nailed and rested on a 2×2 ledger strip. I removed the ledger strip in sections and installed Simpson Strong-Tie LUS28 joist hangers with SD #9 x 2-1/2 screws at the other joists, but it’s difficult to fit a joist hanger with a DTT2Z deck tension tie and bolts. Is a joist hanger needed with a Simpson DTT2Z? Both the Georgia deck code and Simpson Technical Bulletin documents and illustrations don’t say if a joist hanger is needed with hold down anchor. The solutions are:

- Install an LUCZ concealed flange joist hanger which won’t obstruct the bolts and deck tension tie.

Concealed flange joist hangers are only for new construction because it must be installed before setting the joist. That won’t work for my situation. - Install a Simpson ML26Z angle with SDS 1/4″ x 1-1/2″ screws on the other side of the 2×8 joist in lieu of a joist hanger.

The angle is easy to install and designed to resist vertical shear similar to a joist hanger. Simpson appears to use this method in this photo. You can just see the metal angle on the opposite side of the joist near the top center of the photo. - Set back the DTTZ hold down anchor back from the deck beam to allow clearance for the flanges and screws of a standard joist hanger.

This particular joist is tilted to the left (out of plumb) and I was able to fit a standard joist hanger. In the future I’ll install an ML26Z angle when rebuilding the rail.

See this discussion on DIY Chatroom for other opinions.

Guard Post Next to the House Wall

The old guard post was set against the house wall and the narrow space between the two would fill with leaves and seeds. I set the new guard post back several inches so debris would pass through. Notice the holes in the ledger board flashing because the deck boards were incorrectly installed parallel to the deck joists. I’ll replace the flashing when I replace the deck boards. I soaked the top of the 2×10 beams with Copper-Green Brown wood treatment and sprayed it into the nail holes where I pulled off the pickets and old post.

Blocking is required when a guard post is mounted to an outside beam or joist with two Simpson DTT2Z deck post connectors installed on opposite sides. The blocking is either toe-nailed or fastened with SD #9 x 2-1/2 inch screws. It was easier to pull up the decking to install the blocking while sitting on the deck:

Detail of the middle guard post installed with Simpson DTT2Z’s and blocking:

The new guard posts are installed and I’m tearing off the old railing in sections:

Install the 2×4 Top and Bottom Deck Rails

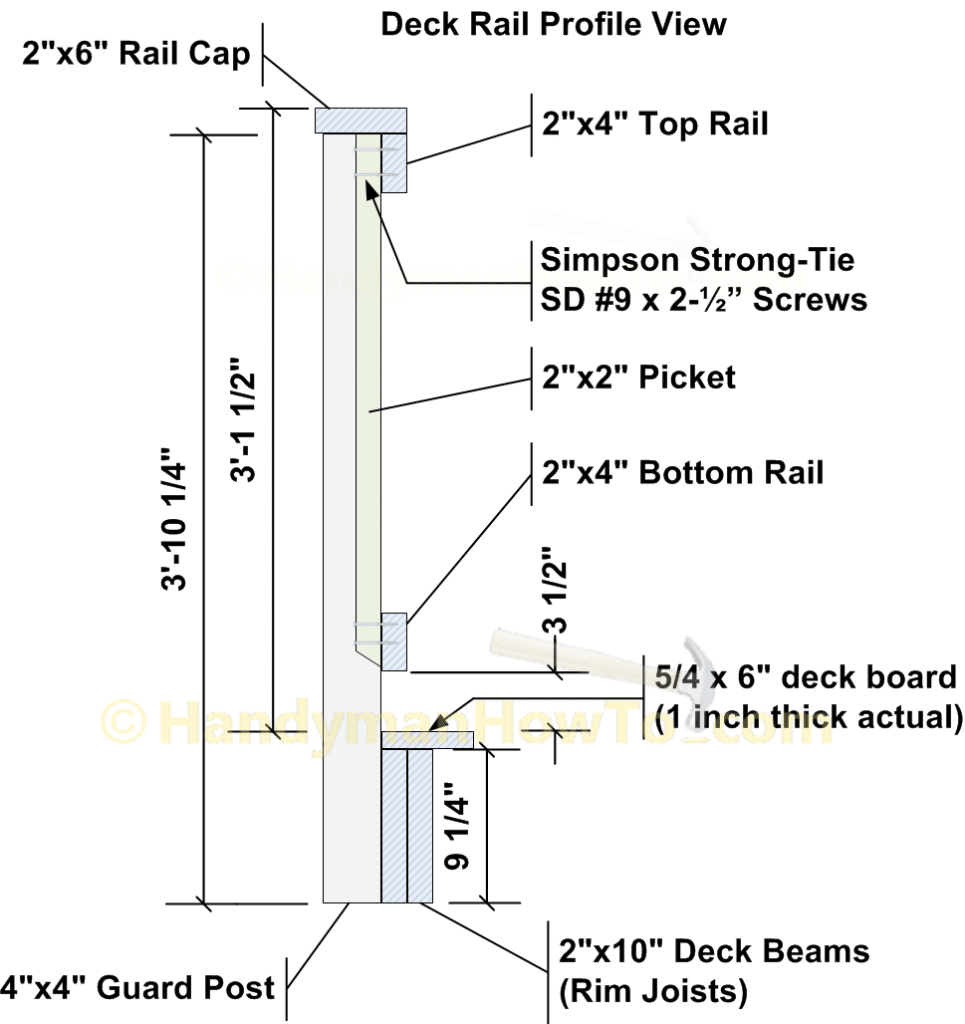

The #2 pressure treated 2×4 top and bottom rails are attached to the guard post with two Simpson Strong-Tie SD #9 x 2-1/2 screws at each post. See Figure 27 “Typical Guard Detail” on page 15 of the Georgia Prescriptive Deck Code for the screw placement details.

2×6 Rail Cap

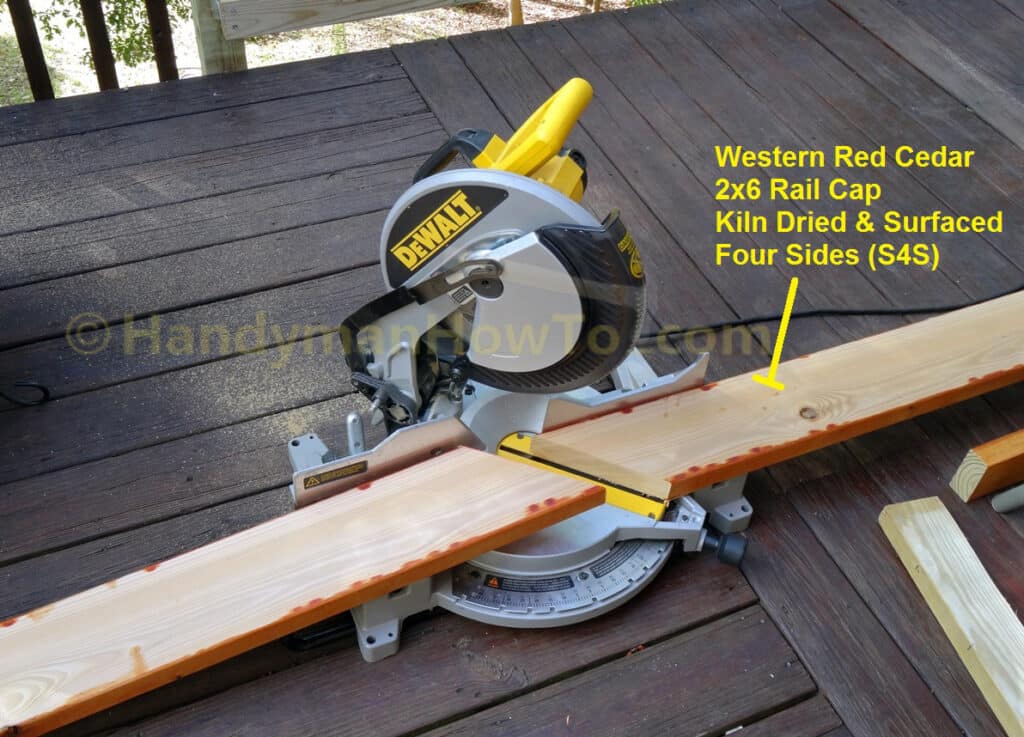

The deck building code requires a 2×6 rail cap or equivalent width material. I chose kiln dried Western Red Cedar which looks nice and is rot resistant. Check your local lumber yard if the big box home improvement stores don’t have the Cedar lumber. I’ve made the 45 degree miter cut for the deck corner:

The 2×6 cedar rail cap is fastened with #8 x 2-1/2 deck screws. The new rail is nearly finished, just need to install the pickets:

Closeup of the 1/2 inch guard post bolts and blocking:

The deck rail after a 2nd coat of redwood stain toner. The toner darkens with age to match the rest of the deck.

Deck rail corner detail. Installing two 4×4 guard posts at the corner is so much stronger than the original single notched post. The new deck rail is very strong and stiff:

2×2 Pickets

I purchased 2×2 inch by 8 feet long #2 grade pressure treated Southern Yellow Pine lumber, measured and sawed the pickets. The pickets are cut to span the distance from the 2×4 top rail to the 2×4 bottom rail with a 25 degree angle bottom cut for a drip-edge. My DeWALT miter saw was ideal for fast and precise cuts. Each picket is fastened with four (4) Simpson Strong-Tie SD #9 x 2-1/2 hex screws, which exceeds the #8 screw deck code requirement. This design complies with the Georgia Amendments Prescriptive Deck Details based on the 2012 International Residential Code per Figure 27 “Typical Guard Detail” on page 15. I prefer screws instead of nails because screws hold better than nails and can be easily removed to replace a picket.

I chose to mount the pickets outside the rail for a smooth and nicer looking rail.

Simpson SD #9 x 2-1/2 compared to #8 x 2-1/2 Wood Screws

The galvanized Simpson Strong Drive (SD) #9 x 2-1/2 inch hex head screw embeds equally deep in the wood as a #8 x 2-1/2 exterior wood screw. The SD screw is better for fastening 2×4 rails and pickets owing to the flat hex head which won’t push apart the wood like the bugle head #8 wood screw:

I do install the #8 wood screws when the screw head needs to be even with the wood surface, for example in the 2×6 cap rail and 5/4 deck boards.

The SD #9 screws are easy to drive and hold firmly with a magnetic 1/4 inch hex drive. Not having to hold the screw in your fingers is highly convenient when leaning outside the deck rail and hanging on with the other hand.

The 2-1/2 inch SD #9 screw is ideal for fastening 2x lumber without under- or over penetration:

Install the Deck Rail 2×2 Pickets

I drilled 1/8 inch strain relief holes for each screw to prevent cracking or splitting the pickets.

The deck code requires the pickets to be spaced such that:

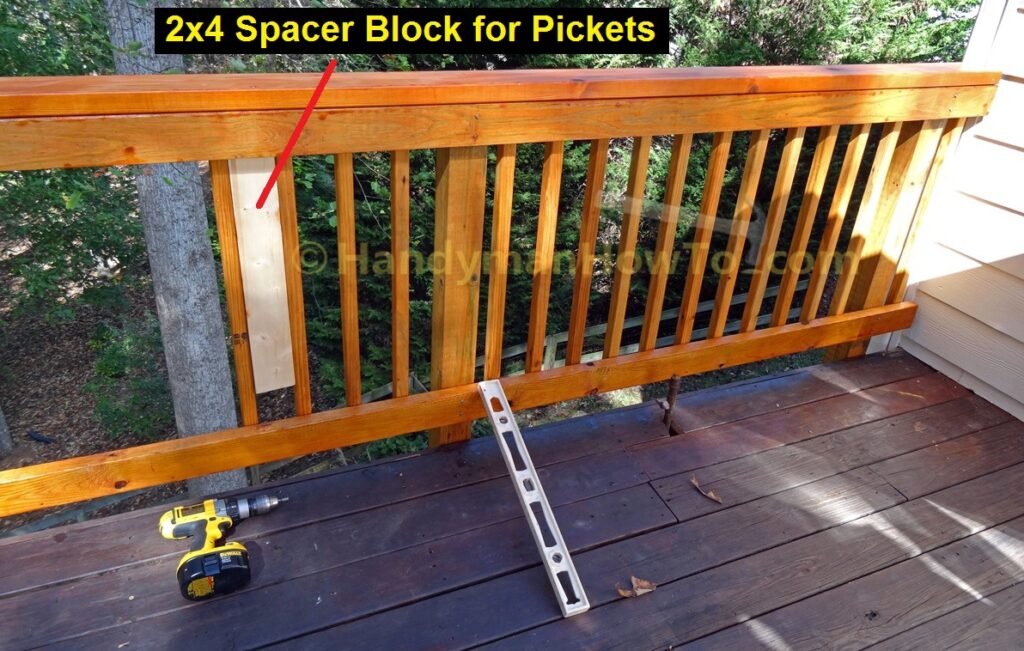

“openings shall not allow the passage of a 4 inch diameter sphere; wet lumber must be spaced such that when shrinkage occurs, the maximum opening is maintained”

A kiln dried 2×4 block is ideal for spacing the pickets with 3-1/2 inch openings. Check each picket for plumb with a level, then fasten with four screws. I set the pickets tight against the block – which holding the block here:

When installing pickets next to a 4×4 guard post, one side may have an opening less than 3.5 inches and that’s OK per the deck code requirements. Resume the 3.5 inch spacing between pickets on the other side of the post:

View of the installed pickets. A couple of the SD #9 screws drove a little below the face of the picket because some pickets were softer than others. I had to adjust the torque on my cordless drill to prevent over driving. This photo was taken after a 2nd coat of redwood stain toner:

Deck corner construction closeup. Take care the space between the pickets at the corner is less than 4 inches wide:

The rebuilt deck rail. A plus for the new deck rail is the leaves go under the rail instead getting caught against the pickets like they did with the old rail when using the leaf blower:

I’ll rebuild the rest of the deck rail to match the new rail after replacing those deck boards that are incorrectly installed parallel to- instead of across the joists.

I’m back to working on the new 6×6 deck post in How to Install Deck Post Knee Braces.

Hope this helps,

Bob Jackson