This tutorial shows how to crimp round duct pipe with a 5-blade crimp tool for joining sections of sheet metal duct.

Sheet Metal Duct Pipe Crimp

Factory made sheet metal duct pipe and fittings have a 1-1/2 inch wide male crimp band to easily fit one section of pipe into the next. The crimp band makes the pipe a bit smaller in diameter and cone shaped for easy joining. The factory crimp band is illustrated below for a sheet metal start collar and elbow:

It’s often necessary to cut a section of sheet metal round duct pipe while installing HVAC ductwork. With careful planning, the duct pipe can be cut such that the factory crimp band section is retained with the piece to be installed and avoid the need to manually crimp the pipe. I had this fortunate situation when I installed my sheet metal ductwork and didn’t need to manually crimp the duct pipe.

Manually crimping duct pipe may be necessary when reusing previously cut pipe sections or if your pipe lacks the factory made crimp band.

How to Crimp Round Duct Pipe

For this demonstration I’m working with a scrap section of 12 inch diameter 30-gauge round sheet metal duct pipe leftover from my attic ductwork upgrade to illustrate the use of the pipe crimp tool. In practice the factory crimp band would not be present because it’d be simpler to cut the smooth end of the pipe to length and keep the factory crimp.

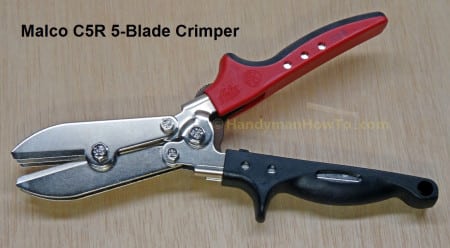

I purchased a Malco C5R 5-blade crimp tool for my sheet metal duct installation job because it’s a highly rated quality item. The compound linkage and blades worked smoothly with no slop or wiggle. The tool locks in the closed position by moving the brown thumb lever located at the front of the red grip handle.

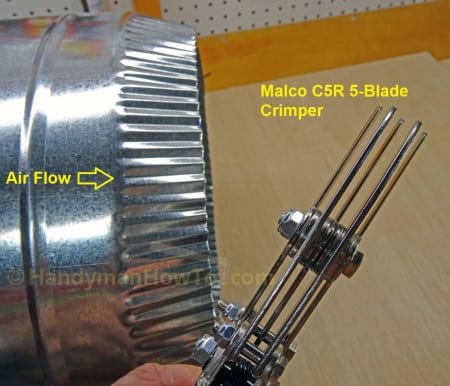

Crimping the sheet metal duct is simple, place the crimp jaws over the pipe end and squeeze. The C5R tool compound linkage provides lots of leverage with minimal effort:

Work around the duct pipe using the previous set of furrows to index the crimp tool for the next crimp:

Slide the crimp tool onto the duct pipe and squeeze to make the next crimp with perfect spacing:

The MALCO C5R Crimper did a really nice job. The crimp band is uniform with a nice reduction in the duct pipe size.

Aside: The duct pipe and fittings should always be installed so the direction of air flow is towards the pipe crimp (or male end) as indicated by the arrow.

Another view of the manual pipe crimp. The crimp tool can cause one side of the double fold snap-lock seam to bend upwards. If that happens, place the pipe end on the corner of the workbench and tap the seam flat with a hammer.

The newly crimped pipe will be joined with a 5 foot section of snap-lock sheet metal duct pipe on the left:

The two sections fit perfectly and are ready to be fastened with sheet metal screws then sealed with mastic.

Thanks for reading,

Bob Jackson