This project shows how to install a Honeywell Ultraviolet Light Treatment System on the air conditioner rigid duct board plenum to inhibit mold and mildew growth on the air conditioner evaporator coils, drain pan and insulation.

An ultraviolet surface treatment system emits UV-C light for germicidal disinfection to kill mold and mildew growing inside the air handler, akin to giving the microorganisms a very bad case of sunburn. The Honeywell Surface Treatment UV light is mounted on the side of plenum just above the A-frame evaporator coils to bathe coil case in UV light. UV light in invisible to our eyes, the lamp also produces blue light which is seen here. UV light is harmful to your eyes and skin, never look into the light – I set the camera on a tripod with a timer for this photo:

Are UV Light Treatment Systems Effective?

The effectiveness of air conditioner UV light treatment systems depends on many factors including placement, wattage and quantity of UV lights with respect to the air conditioner surfaces to be sanitized. According to the Residential Air Cleaners (2nd Edition): A Summary of Available Information by the United States Environmental Protection Agency (EPA) (bold emphasis added):

[Ultraviolet Germicidal Irradiation] UVGI cleaners in a surface disinfection application are installed in air-handling units to prevent or limit the growth of vegetative bacteria and molds on moist surfaces in the HVAC system. One study reported a 99-percent reduction in microbial contaminants growing on exposed HVAC surfaces, but a reduction in airborne bacteria of only 25 to 30 percent. One reason that the surface disinfection application provides only a slightly noticeable reduction in airborne microbial concentrations may be that microorganisms in the airstream are exposed to the UV light for a shorter time. Conversely, microorganisms growing on exposed HVAC surfaces are given prolonged direct UVGI exposure. Another study found that UV lamps yielded somewhat lower levels of mold in the fiberglass insulation lining the air-handling unit.

Risks and Benefits of UV Light Treatment Systems

The risks of residential UV light treatment systems are it can attack and breakdown many rubber and plastic materials over time, for example:

- rubber materials, gaskets, etc.

- plastic air conditioner drain pans

- exposed plastic parts of whole home humidifiers mounted on the supply- or return air plenum

- the inner plastic liner of flexible air duct

Certain plastic materials are rated for UV light exposure, so check with your air conditioner or duct work manufacturer if in doubt.

The benefits of residential UV light treatment systems are:

- effective at killing mold and mildew on air conditioning coils, drain pan and other exposed surfaces inside the air handler

- can reduce or eliminate the “smelly gym sock” odor caused by mold

- may be effective at killing airborne microorganisms

- less frequent need for evaporator coil and drain pan cleanings

- a 2nd or maybe 3rd line of defense for keeping your air handler clean

Before Installing a UV Germicidal Light

The following Indoor Air Quality (IAQ) items should be addressed before installing a UV Germicidal Light (UVGI) in the air handler.

- High Quality Air Filter

A high quality air conditioner filter that is changed on a regular basis is critical for preventing airborne dust, mold spores, dander, pollen, etc. from reaching the air conditioner evaporator coils. Organic dust and dirt is a food source for mold in the damp environment of the cooling coils, so it’s critical to keep out as much as possible.

Tip: I seal my air conditioner filter slot with aluminum foil HVAC tape to prevent outside air bypassing the filter. -

Regular Air Conditioner Maintenance

UV light can only disinfect surfaces upon which the light shines and won’t kill mold in shaded areas. Traditional chemical coil cleaning methods should be used to remove mold and dirt when necessary. Have your central air conditioner system inspected and maintained by a licensed HVAC technician at twice yearly before the heating and cooling seasons. -

Keep the Household Humidity Below 50%

The EPA recommends keeping the relative humidity below 50% to control dust mites and not more than 60% to control mold:Humidity and Microbial Growth

In addition to thermal comfort, the control of relative humidity is important to limit the growth of microorganisms such as mold and dust mites. To control microorganisms, it is best to keep relative humidity below 60% (to control mold) and 50% (to control dust mites) at all times, including unoccupied hours. High relative humidity can foster proliferation of mold and dust mites. See also www.epa.gov/moldThe air conditioner dries the air as water condensates on the cold evaporator coils and flows into the drain pan. Adjust the thermostat temperature setting a degree or two colder until the humidity levels are below 50%. Also remember to run the bathroom exhaust fan while taking a hot shower to limit the amount moisture being added to the air.

Why I Chose a Honeywell UV Light Surface Treatment System

There are many manufacturers and models of UV germicidal lights for residential air conditioning systems, however most are sold only to HVAC installers and not available for purchase by the Do-It-Yourself homeowner.

The reasons I chose to install a Honeywell UV100A1059 UV Light Surface Treatment are:

- UV-C ultraviolet germicidal lamps are effective at killing mold on cooling coils.

- I thought it would be a useful addition to my air conditioner system.

- The Honeywell UV100A1059 was affordable, my cost was about $160.

- Simple to install and operates on 120VAC power from a residential grounded outlet.

- 36 watt bulb (total).

- Does not produce ozone.

The UV100A1059 mounts on the side of the air handler plenum such that the dual mercury lamps shine on the evaporator coils:

Front side of the UV100A1059:

The Honeywell UV100A1059 components snap together without tools:

- Base unit

- Lamp socket

- Mercury UV bulb

The bulb extents about 14-1/2″ past the base unit into the air handler.

How to Install a Honeywell Ultraviolet Light Treatment System

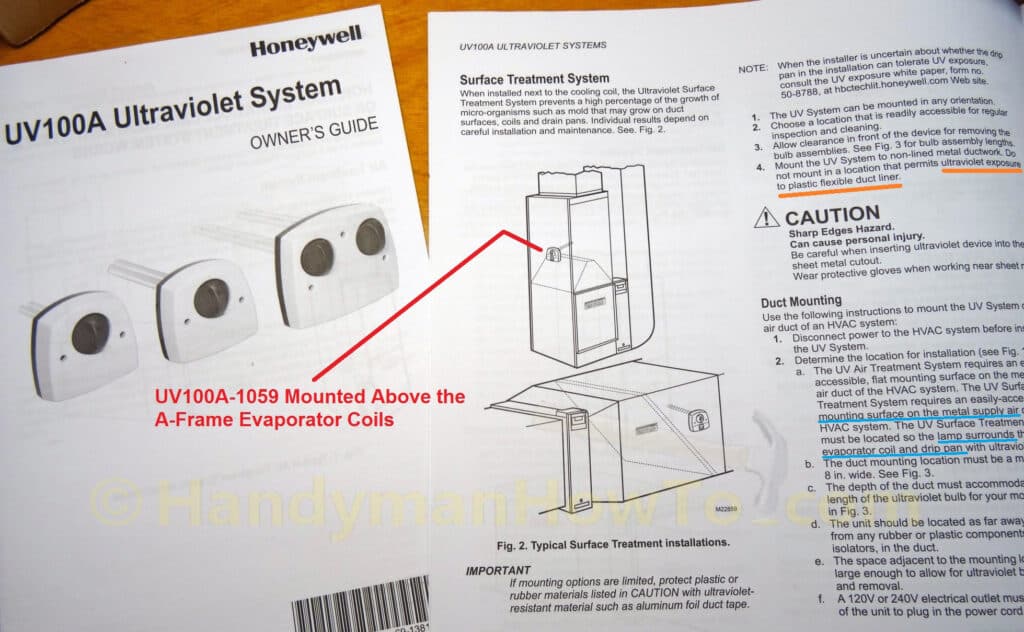

The Honeywell UV light will be installed just above the A-frame evaporator coils on the side of the plenum box as illustrated in the Honeywell UV100A1059 installation guide:

The UV100A1059 installation instructions says to:

“Mount the UV System to non-lined metal ductwork.”

however my supply air plenum is made of 1″ rigid duct board for which Honeywell advises (bold emphasis added):

“… due to the lack of strength of the duct board material, we do not recommend mounting UV devices on a vertical duct board surface without additional structural supports.”

Not a problem! I’ll mount the UV100A1059 light to a 16 gauge sheet metal mounting plate fastened with aluminum foil HVAC tape to the rigid duct board plenum.

UV Light Sheet Metal Duct Installation

If you happen to be installing the UV treatment lamp on a metal duct work, see the following Honeywell YouTube video for an overview. Note that this video shows how to install the Air Treatment UV lamp on the return air duct which is empty space. Be extra careful if installing the Surface Treatment UV lamp on the metal supply air plenum to ensure you haven’t measured incorrectly and accidentally drill into the coils!

UV Light Rigid Duct Board Plenum Installation

Plenum Measurements

Measure your supply air plenum to ensure it is wide enough for the UV100A1059 lamp to fit across the A-frame evaporator coils such that the lamp will shine on both sides of the coils. The UV100A1059 lamp extends about 14-1/2 inches into the plenum. It will most likely be necessary to remove the evaporator coil access panel to accurately measure the interior width of the duct board plenum.

UV Lamp Mounting Template

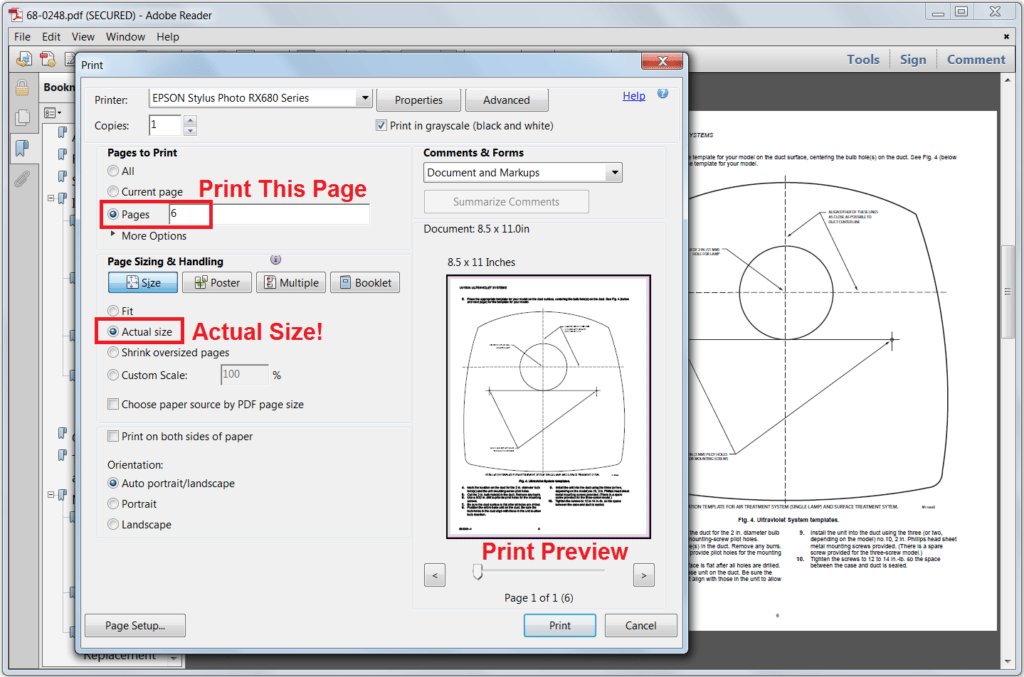

The full size UV100A1059 mounting template is included in the product installation guide shipped with the unit. You can use the template from the guide, or print your own from page 6 of the online manual. I chose to download and print a copy of the mounting template because I’m a fastidious person and like to keep my manuals in the original condition.

If printing a copy of the mounting template, be sure to select “Actual Size” size option in Adobe Reader for true measurements:

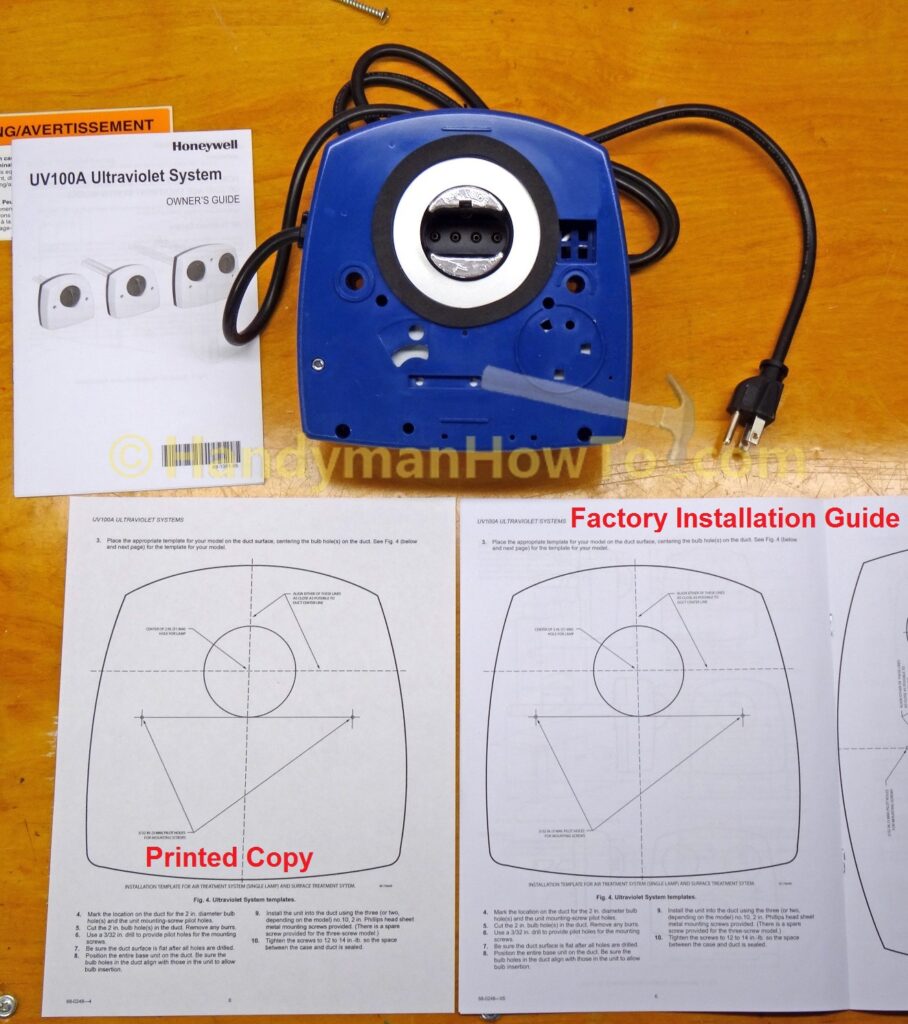

My copy of the installation template is on the left:

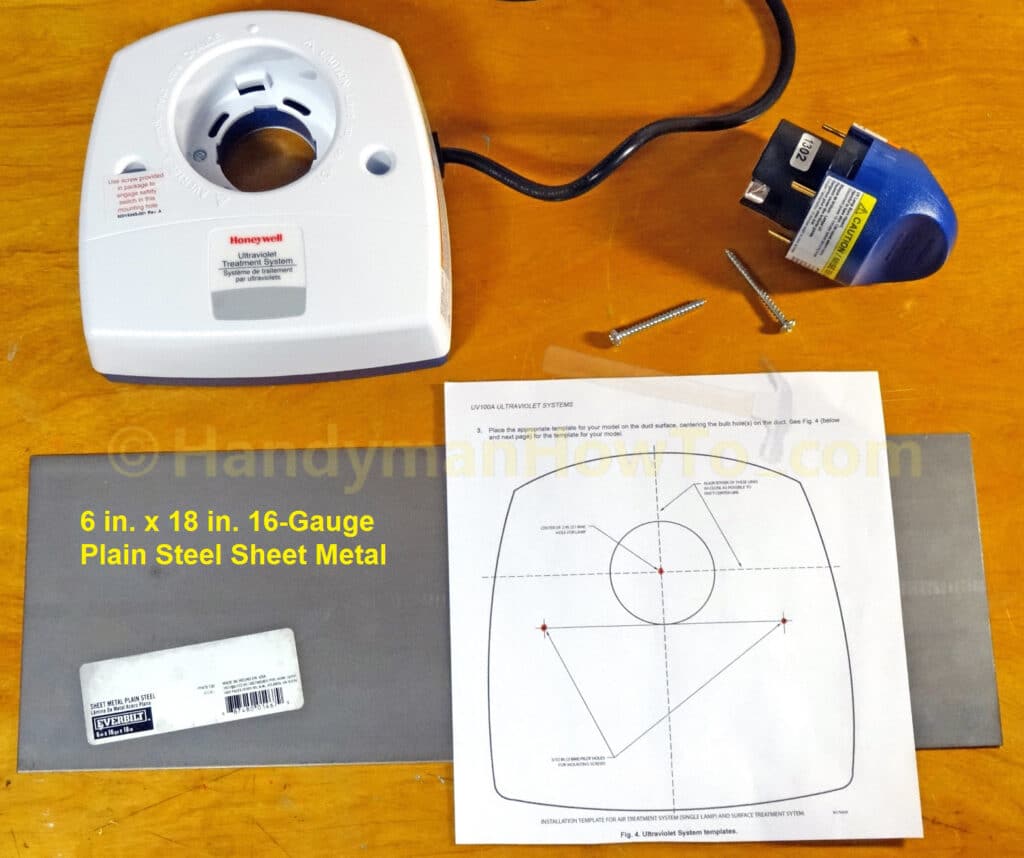

I bought a 6 inch x 18 inch 16 gauge sheet metal plate to mount the Honeywell UV light. The two screws will be driven into the metal plate to mount the UV light. I don’t recommend using a lighter gauge steel such as 18 or 20 gauge because it’s thinner and may not hold the screws as well as the thicker 16 gauge sheet metal.

The Honeywell UV light will be mounted on the side of the rigid duct board plenum, which is 18 inches deep (front to back exterior measurement). The 18 inch long sheet metal plate will be cut with tin snips to 14 inches long, leaving a 2 inch margin for the HVAC tape at both ends.

The 16 gauge sheet metal mounting plate cut with tin snips to 14 inches long. The trimmed section (short section on right) will curl somewhat while cutting. If the main section develops a twist, place the cut end in a bench vise and clamp the jaws shut to straighten it.

This project is continued in How to Install a Honeywell Ultraviolet Light Treatment System – Part 2.

Thanks for reading,

Bob Jackson