This project shows how to repair garage door safety sensor wires that are broken or damaged with quick and easy butt splice connectors.

Garage Door Will Not Close

My wife said the Chamberlain garage door opener would open, but not close the garage door. Not good news before breakfast on Sunday morning. A brief inspection found the problem: a squirrel was trapped in the garage overnight and chewed through the safety electric eye sensor wires:

The squirrel chewed through the garage door photo-sensor wires on both sides of the door in it’s attempts to escape and even gnawed on the window blinds.

The garage door safety sensors operate by shining an invisible beam of light across the floor to detect if an object is blocking the door. If the door safety beam is broken by a person, animal or other object the garage door opener assumes the door is blocked an will not close to prevent injury. Sensors can be knocked out of alignment which also prevent the door from closing. Obviously, I that’s not the problem here.

How to Repair Garage Door Safety Sensor Wires

Because the squirrel left about 3 inches of undamaged wire attached to the Chamberlain garage door safety sensor, I was able to quickly repair it by splicing in a new section of 22 gauge garage door wire using telephone butt splice connectors:

I’ve done my share of telephone wiring and garage door opener installations over the years and had a roll of wire and butt splice connectors in my workshop that were left over from previous jobs. Had the squirrel chewed the wires completely off the safety sensor, my only option would be to buy new sensors which include ~20 feet of wire.

Telephone Butt Splice Connectors – Scotchloks

Telephone butt splice connectors (a.k.a. Scotchlok) are crimp-on gel filled Insulation Displacement Connectors (IDC) that pierce the wire insulation with U shaped metal blades to make a permanent splice connection. The red cap is filled with a gel sealant that when crimped, squeezes out around the wires for moisture resistance. Makes a perfect connection every time without stripping the wires!

The Chamberlain replacement safety sensor installation manual shows butt splice connector wiring on page 3 in illustration 4A.

My local home improvement store doesn’t carry the name brand 3M Scotchlok connectors, so I’m using the red Ideal 85-925 3-Wire Butt Splice IDC product.

Do not use the yellow two-wire butt splice connector because the 22 gauge garage door wire insulation is too thick and will not fit the conector.

The telephone butt connectors are designed for solid copper wire conductors, stranded (or twisted) wire will not work reliably. So be sure to use 22 gauge, 2-wire solid conductor garage door wire. Garage door wire with an red or black wire identification stripe is available at most home improvement stores.

Garage Door Safety Wire Repair: Butt Splice Connection

The wire splice repair is made as follows:

- Trim off the damaged wire leads at the garage door safety sensor.

Cut the ends off square (not slanted) so the leads will fully seat in the butt splice connector. - Cut a generous length of new garage door opener wire.

Make it at least 12 inches longer than necessary. It will be cut to length later. - Pull apart the striped and plain wire leads so about 1-1/2 inches is free.

You may need to make a small knife cut lengthwise between the two wires to get a grip and pull the wires apart. Do not strip the wire insulation. - Insert the red or black striped wires fully into the butt splice connector until the wires are fully seated and will go no further.

Closeup of the fully seated wires in the telephone butt splice connector:

Crimp the butt splice connector closed. This will force the red button into the connector and actuate the internal metal blades that piece the wire insulation to make the electrical connection. There are special tools for making crimp connections, pliers work fine too, just check the red button is evenly seated all the way in the connector housing:

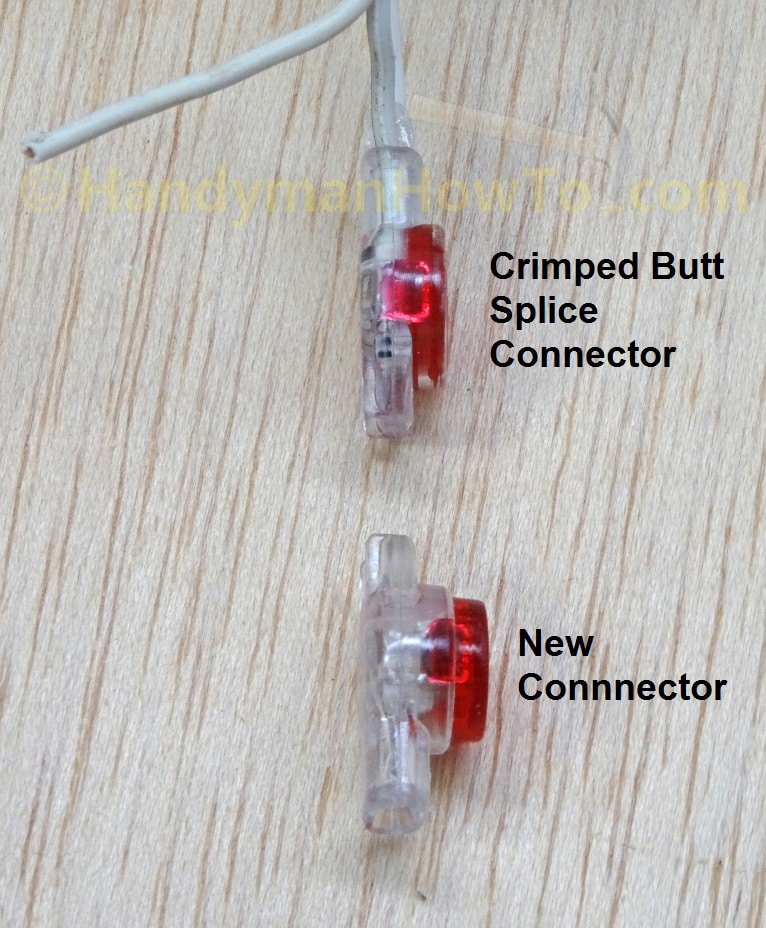

Comparison of the crimped connector with a new connector:

The sealant in the gel filled cap is squeezed out when the connector is crimped for moisture resistance. Telephone butt splice connectors sure beats stripping and twisting wires then wrapping with electrician’s tape!

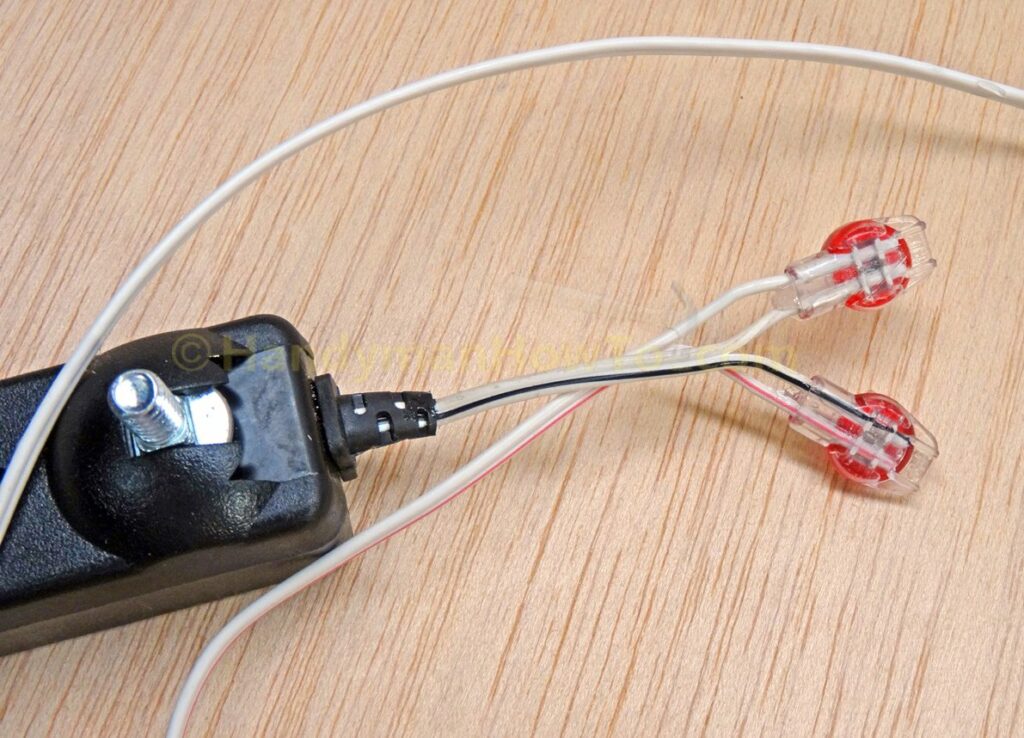

After crimping the striped wires, connect the plain wires. You can see how the wires are captured by the two metal blades that pierce the wire insulation. The butt splice connectors make for a professional looking job.

Below is the garage door safety sensor with the new section of wire spliced in. I’ll need two more butt splice connectors to finish the job. The red wire cutter/stripper was used for making clean wire cuts. The blue electrician’s pliers are designed for much heavier wire and its wire cut tended to mash the wire insulation into an oval shape, making it difficult to insert the wires into the butt splice connector.

Garage Door Sensor Wire Repair

Unplug the garage door opener from the electrical outlet and remove the power-fail battery (if equipped) to avoid an electrical short and possible damage to the garage door opener. I measured the door sensor wire voltage and it was only 6 volts DC, therefore electrical shock isn’t a concern but possible damage to the door opener circuitry is.

Repeat the above steps to make the butt splice connector wire repair, in summary:

- Cut off the damaged wire end that goes to the garage door opener.

- Match and connect the striped wires and plain wires with butt splice connectors.

- Mount the safety sensor to the door bracket via the wing nut.

- Restore power to the garage door opener.

- Check the green and amber LEDs on the sending and receiving safety sensors are illuminated.

- It will likely be necessary to realign the safety sensors.

- The amber sensor LED is always illuminated because it sends the invisible beam. The green LED illuminates only when the beam is received.

- Check the garage door for correct operation.

The garage door is working fine. I replaced the single wire staple to keep the wires out of the way:

Squirrel Strikes Back!

The garage door was open for maybe 30 minutes while I repaired the wires. I’d walked around the garage looking to see if the squirrel was hiding and slapped the car to scare it outside just be sure. An hour or so after closing the garage door I heard noises in the garage, went out and pressed the garage door button. The garage door wouldn’t open! The squirrel had chewed through both wires again!! Dang!

I guessed the squirrel was hiding underneath the car the entire time I was working. I parked the car in the driveway, repaired the sensor wires a second time and checked everywhere looking for the squirrel. I never saw the squirrel and there hasn’t been anymore problems.

My new plan is the run the sensor wires in armored aluminum conduit to prevent future problems, which will require re-splicing. Sigh.

Take care,

Bob Jackson