This project shows how to saw slots for a low profile kerf-mount door bottom weatherstrip in the door outer wood frame. This project is continued from How to Repair a Rotted Door Bottom and Weatherstrip – Part 1.

I wasn’t satisfied with the U-shaped weatherstrip, so I took the patio door back off the hinges and cut two groves (or channels) in the new door bottom to attached the original style kerf-mounted weatherstrip – a Frost King UDS36 model.

The Rotozip Spiral Saw with a Jigsaw Handle Kit and Straight Edge Guide made the job easy:

U-Shaped Door Bottom Weatherstrip

I removed the French door and set it back in the door jigs in my workshop. Notice the dark spots on the concrete floor from water dripping from the inside the door sweep. If you install a U-shaped or clamshell style doorsweep, be sure to caulk the top seam and screw heads to prevent water from seeping inside. Note the Frost King instructions state the screws go on the exterior side of the door, exposed to the weather.

Removing the weatherstrip was simple, just remove the screws and slide off the weatherstrip.

Saw Door Bottom Grooves for New Weatherstrip

I bought a Rotozip Jigsaw Handle Kit that includes a Straight Edge Guide (Editor’s Note: unfortunately, this kit is no longer available). The ability to use the Rotozip as a router to cut the door bottom groves made this an obvious choice. If you have a router and straight edge attachment, that would also work fine. The jigsaw handle kit comes with everything you see here.

Two straight pieces of scrap 2×4 boards were fastened together with wood screws and clamped to the bottom of the patio door to provide a wide base and edge for the straight edge guide.

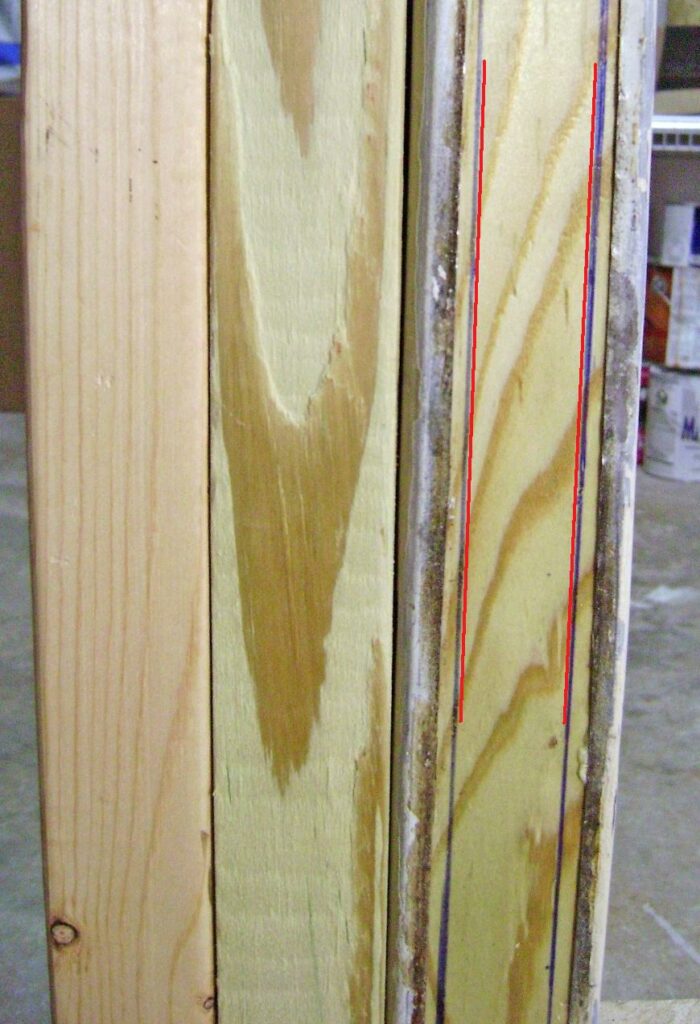

The following photo illustrates the setup. A section of new kerf-mount weatherstrip is held against the door bottom to illustrate the two slots (red lines) to be cut in the door bottom with the Rotozip for the spines. The Frost King UDS36 weatherstrip is 36 inches long and my door is 32 inches wide, so I’m using the extra 4 inches of weatherstrip for a guide.

Two blue lines are marked with a straight edge for the cuts. The red highlights are added for clarity in this photo. The lines – and corresponding cuts to be made – stop 1 inch from the ends of the bottom frame.

It’s necessary to select a Rotozip bit that matches the width of the weatherstrip spines. The bits are compared to the spines on the weatherstrip. The 5/32 inch bit would seem to be the correct size, but in reality it cuts a channel (leaves a kerf) that is too large because the bit tears away a slightly larger amount of wood than the diameter of the bit. The right choice is the 1/8 inch bit on the left. I made test cuts on scrap wood to decide which bit is best.

The jigsaw handle was adjusted such that the depth of the bit – and the corresponding groove was about 1/8 inch deeper than the spine of the weatherstrip. However, the Rotozip bit was too long for the maximum height adjustment of the jigsaw handle and would have resulted in a cut that was far too deep. I therefore used a Dremel Tool and cutoff wheel to shorten the unfluted end of the bit by about 1/2 inch. This allowed me to make the shallow cut needed for the spines without slicing through the 3/4 inch thick wood frame.

To make the cuts:

- Put on your safety glasses.

- Make sure the Rotozip is turned off.

- Set the tip of the drill be on the line to be cut.

- Tip the saw forward (up in my case) such that the straight edge guide catches the outer 2×4.

- Adjust the depth of the edge guide and tighten the lock screw.

- Recheck the alignment.

- Turn on the Rotozip.

- Hold the straight edge guide firmly against the 2×4.

- Lower the bit into the wood on the marked line.

- Move the saw at a steady pace while holding the fence firmly against the 2×4.

- At the end of your cut, rock the saw downward to raise the bit out of the kerf (i.e. groove).

- Turn off the saw. Redo from Step 3 for the other groove.

I found the Rotozip left a lot of sawdust in the kerf (a.k.a. saw groove or slot) that had to be knocked loose with the tip of a screwdriver and vacuumed out. This was caused by the relatively moist pressure treated wood.

Installation of the new kerf-mounted weatherstrip from this point is identical to this How To article; start at one end of the weatherstrip and set the spines into the kerf with a rubber mallet.

However, I changed my mind here on the orientation of the weatherstrip and placed the tube-side (right side in the photo below) on the exterior side of the door because I had slightly more clearance on the basement patio door, so this seemed to make for a better seal. The Frost King instructions don’t indicate which way it should go and the original weatherstrip had tubular sections on both sides of the weatherstrip with straight fins in the middle.

The final step was to drill two pilot holes in the bottom of the vertical door frames and fasten ends of the weatherstrip with 1 inch pan-head corrosion-resistant wood screws. I put a small dab of exterior caulk in the pilot holes first to seal around the woods screws.

Table Saw

If I were to do this project over again starting back at Part 1, I would have used a table saw to cut two full length slots for the original kerf-mount weatherstrip. I don’t have a table saw, but you can ask friend or stop by a cabinet shop to cut the slots for you.

Hope this helps,

Bob Jackson