The old central air conditioning unit is dismantled and the new Bryant Evolution air handler is installed in the attic.

Series index:

- Old Central Air Conditioning Replacement with New Bryant Evolution High Efficiency System

- New Bryant Evolution Central AC Installation (you are here)

- Bryant Evolution AC Condenser and Ductwork Installation

- Bryant Evolution Connex WiFi Thermostat & MyEvolution Smartphone App Review

Old Central AC System Removal

The HVAC installation crew arrived at 7am to start early before the attic gets hot. They drained the R-22 refrigerant from the old 3 Ton system into a recovery tank for recycling before cutting the copper refrigerant lines. Then the electrical, natural gas, condensate drain line, thermostat and AC cut off float switch are disconnected. The ductwork is disconnected from the supply and return plenums, then the plenums are dismantled. The evaporator coil sits on top of the gas furnace so it’s removed and sat on the attic floor:

The old A-frame evaporators coils sitting in the hallway:

The old plenums, furnace, auxiliary drain pan and condenser are hauled outside (lower right in the following photo). The HVAC company will haul away the old system at no charge:

AC Copper Refrigerant Line Set

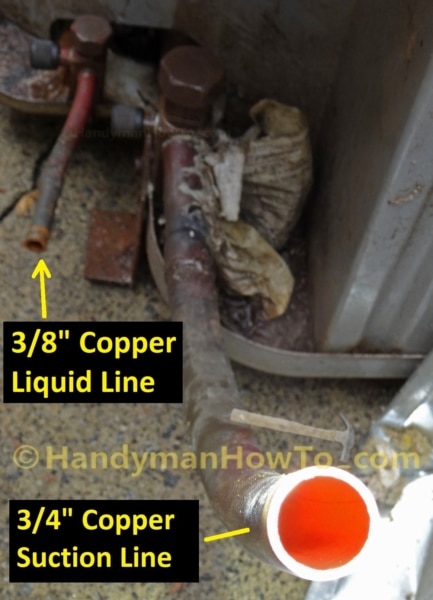

I was concerned if the 17 year old copper refrigerant lines that snaked from the basement up through the interior walls to the attic were in good condition. The 3/4 inch refrigerant suction line on the AC condenser/compressor is noted by the yellow arrow:

I shined a flashlight inside the copper line and it was spotless and bright! No corrosion or contaminates:

I checked the copper line set in the attic and outside the house where the condenser sat. All lines were spotless inside. The lines will be flushed with cleaner to remove any oil and debris before installing the new Bryant Evolution central air system.

Duct Board Return Plenum

The old duct board return plenum has a thick layer of dust but not as bad as some I’ve seen. Duct board has fallen out of favor because the rough surface has greater air flow friction compared to sheet metal duct:

Tip: If you ever sand wood floors or drywall remember to turn Off the central air system and open the windows because the dust will absolutely coat the inside of the ductwork. If drywall dust gets past the air filter it will form a hard clay clogging the evaporator coils. You’ll likely have to replace the coils.

New Bryant Evolution Central AC Installation

With the old AC system out of the attic the workmen hauled the new Bryant Evolution system up in sections. The coils and furnace are narrow enough to fit through the folding attic stairs.

Bryant CAPMP Aluminum Evaporator Coils and 315A Gas Furnace

The new Bryant CAPMP aluminum A-Frame evaporator coil is much taller than the old 3 Ton coil. I wanted a corrosion-resistant aluminum coil and liked the knockouts for UV germicidal lights in the access panel. No need to retrofit a UV system as I did on my old coils.

Looking inside the coils CAPMP3614ALA evaporator coils reveals lots of shiny aluminum and foil faced cabinet insulation. I like how the refrigerant manifold is on the left side for easy removal of the split delta plate to inspect & clean inside the coils. The CAPMP series coils can be installed upright (as shown) or laid on the left side for horizontal air handlers where the 2nd plastic condensate drip pan is located. I asked the dealer about the two green “ground wires” between the coil splash guards and drip pan. The wires simply to provide a path for the condensate to wick into the pan without blowing off:

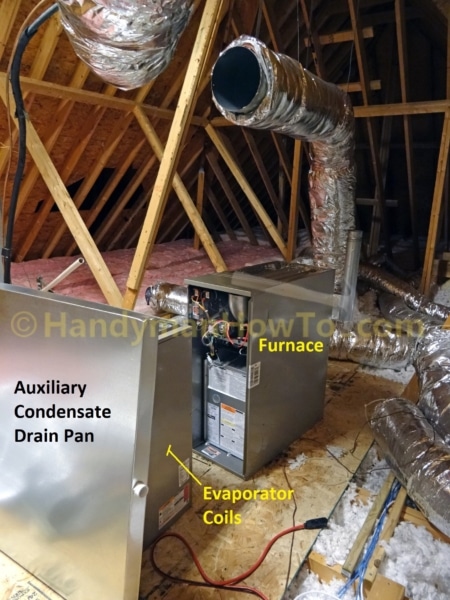

The new Bryant Evolution coils and furnace in the attic ready for installation:

A look inside the Bryant 315A natural gas furnace. The three large panels are the heat exchanger and the blower wheel is just visible in the bottom of the cabinet:

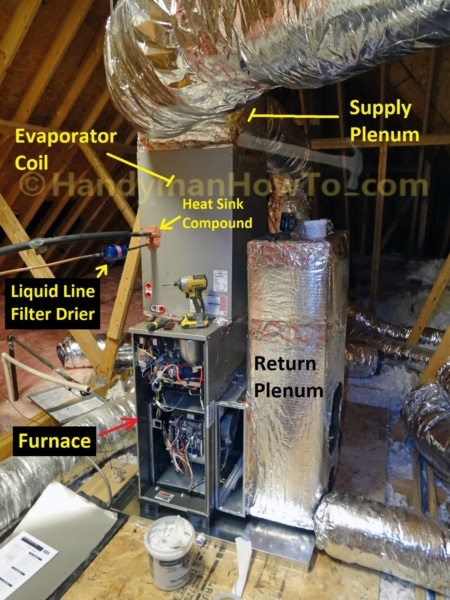

The new air handler installation is coming along nicely with new sheet metal supply and return plenums. The HVAC techs just finished brazing the liquid line dryer filter and copper refrigerant line connections:

Notice the orange colored heat sink compound packed around the copper refrigerant lines at the coil case in the above photo? It’s to protect the Thermostatic eXpansion Valve (TXV) valve from overheating when brazing the lines. Here is a modern silicon-based compound you can use.

Auxiliary Drain Pan – Air Handler Support Blocks

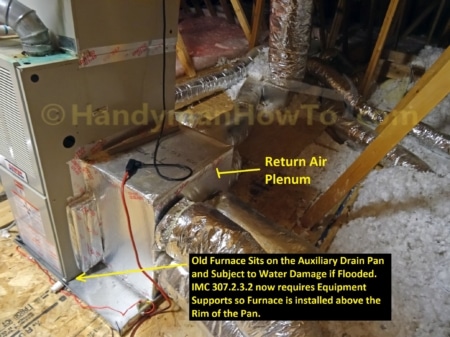

The 17 year old air handler sat on the auxiliary drain pan which could be flooded if the evaporator coil drain line were clogged. The AC cut off float switch will eventually trip to prevent flooding and damaging the drywall ceiling:

A benefit of getting a new central AC system is it must meet the current Building Code, in particular the 2012/2015 International Mechanical Code (IMC) which requires equipment to be installed above the rim of the drain pan:

“307.2.3.2 Appliance, equipment and insulation in pans.

Where appliances, equipment or insulation are subject to water damage when

auxiliary drain pans fill, that portion of the appliance, equipment and insulation

shall be installed above the rim of the pan. Supports located inside of the pan

to support the appliance or equipment shall be water resistant and approved”

Brick supports will meet the building code but the Diversitech FB-1 peel-n-stick furnace mounting blocks looks professional, have waterproof plastic construction that won’t scratch the metal pan or furnace and features a dense blue vibration absorbing pad. Each block can support over 500 lbs. The blocks are available on Amazon.com if you want to retrofit your system:

This series is continued in Bryant Evolution AC Condenser and Ductwork Installation.

Thanks for reading,

Bob