This article compares the pros and cons of different methods of how to wire an electrical outlet, which are:

- Side wiring using the side terminal screws.

- Back wiring using the Leviton Quickwire™ push-in feature, colloquially referred to as “backstab”.

- Back wiring using the screw-and-clamp system.

Leviton Residential & Industrial Grade Outlets

The two electrical receptacles examined are the Leviton 5230-WCP Residential Grade outlet that sells for around $2 and the Leviton 5252-W Industrial Grade (also called “Prograde”) outlet which retails for about $10. Both outlets are rated for 15 AMPs and 125 volts.

Don’t be mislead by the “industrial” or “professional” grade label because the Leviton 5252 series are perfectly suitable for residential use, especially in frequently used locations in the home. Which receptacle you choose is mainly a budget issue. Remember, most houses are built by the low bidder!

Electrical Outlets: Side Wire vs Back Wire

The main difference between side wire and back wire is that in side wiring, the wires are attached using the side terminal screws, while in backwiring, the wires are slid under the terminal clamp.

To side wire and electrical outlet, the wire is stripped, looped around the side screw and the screw is tightened down on the wire. Side wiring is a secure, reliable and widely employed technique. Side wiring is limited to a single conductor (wire) per screw terminal. Side wiring is the done the same way for both the residential and industrial grade outlets.

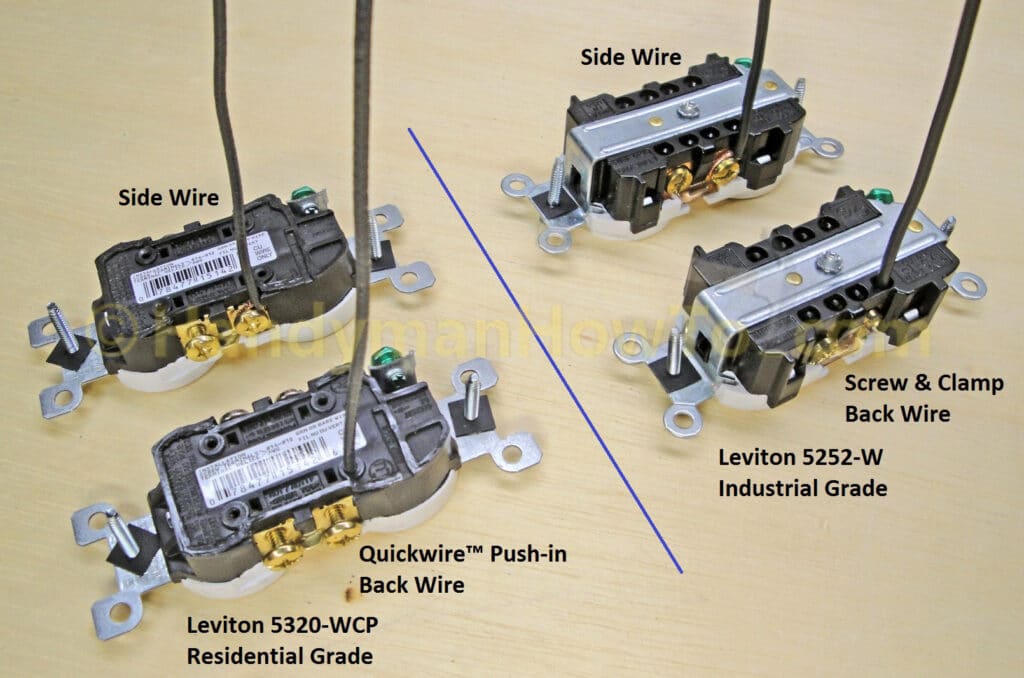

The Leviton residential and industrial grade outlets may be wired in three different configurations as illustrated in this photo:

The Leviton 5230 residential grade outlet (left pair in the photo above) supports:

- Side wiring via the side screw terminals.

- Back wiring via the Quickwire™ push-in (screwless push-in terminal), which accepts 14 gauge (NM-B 14/2) wire only. This wiring method is informally known as “backstabbing”.

The Leviton 5252 industrial grade outlet can be:

- Side wired via the side screw terminals

- Back wired using the screw and clamp system. Underwriter’s Labs refers to this as a “screw-actuated clamp”.

What’s the difference between the wiring methods and why would anyone care? Let’s take a look!

Back Wiring: Differences between Residential and Industrial Grade Outlets

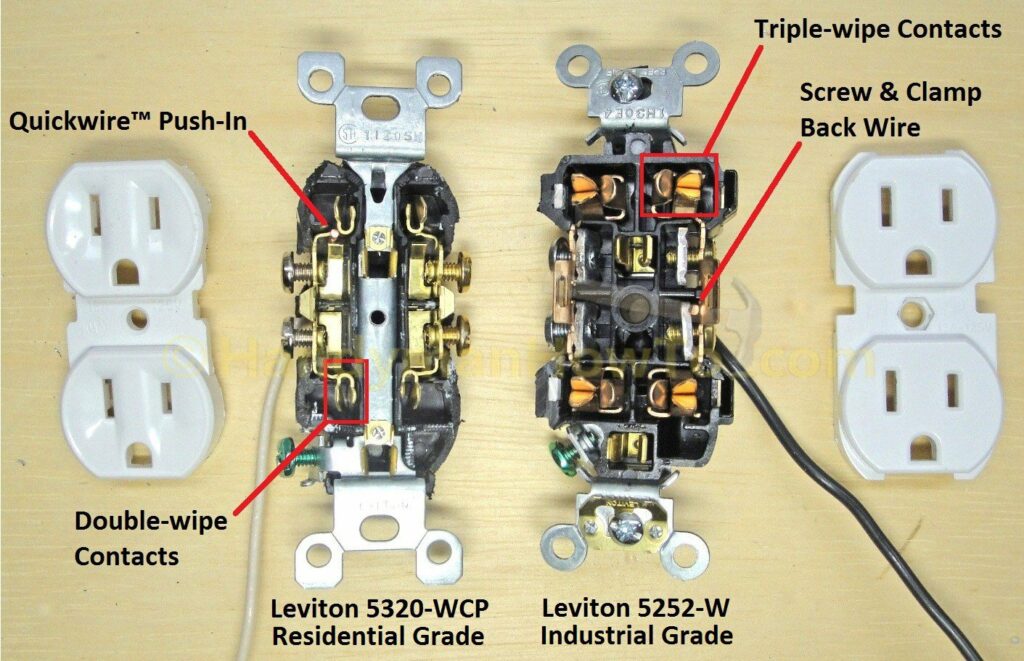

Let’s take a look inside the Leviton residential- and industrial grade electrical outlets for significant differences between the back wiring mechanisms of each:

- The residential outlet (left side) uses a flat spring clamp to capture a 14 gauge only (NM-B 14/2) wire which is pushed in from the back.

- The industrial grade outlet (right side) uses a screw-and-clamp to capture a 10 to 14 gauge wire inserted in the back.

Here’s another look at the Quickwire spring tab terminals compared to the industrial grade screw-and-clamp system. The sturdiness of the two is mechanisms is quite obvious!

The industrial grade outlet is built heavier featuring triple-wipe contacts versus the double-wipe contacts on the residential outlet. The triple-wipe contacts hold a plug more securely and are less prone to wearing out.

Back Wiring using the Leviton Quickwire™ Method

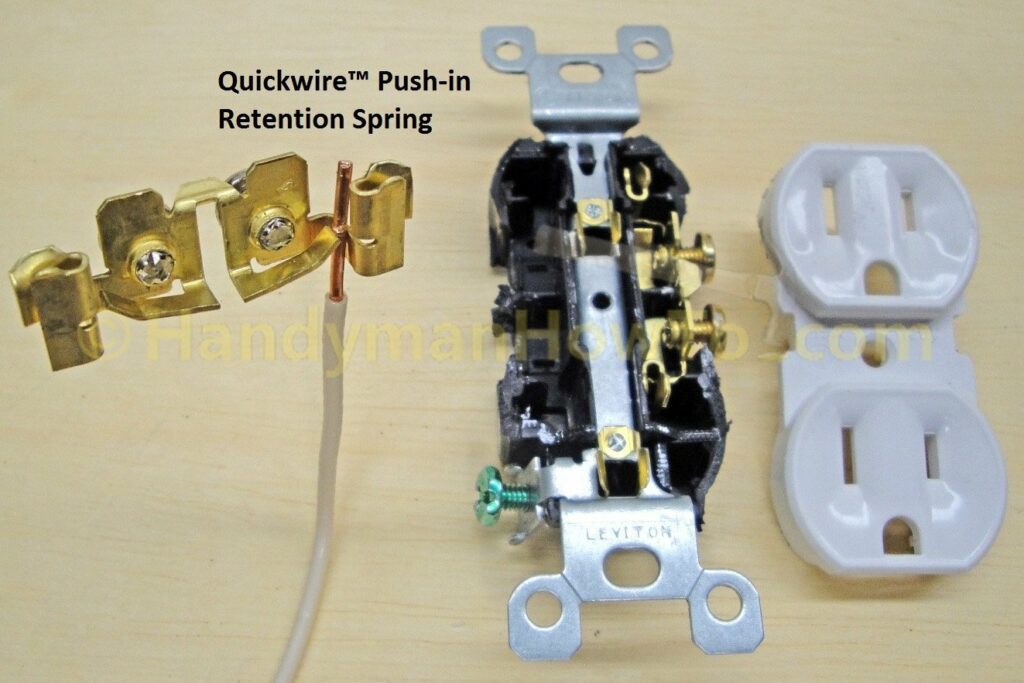

Leviton’s Quickwire push-in method, also known as “backstab”, while being simple and fast to wire, is frequently criticized in the electrical trade as being inferior to side wiring because the flat spring only makes contact with the wire at the edge and allows the wire to rotate and/or wiggle. The movement can build up over time as plugs are inserted and removed from the outlet, weakening the connection and possibly coming loose. Loose connections can cause arcing, excessive heating and interrupt power to the outlet. How many outlets do you have in your house that press inward as you plug something in because the wall box was poorly installed? The outlet isn’t at fault, but shoddy workmanship mounting the wall box aggravates the problem.

The Quickwire outlet has a small rectangular hole in the back to insert the tip of a screw driver to release the wire. I’ve found from personal experience the flat spring noticeably weakens when the wire is released and therefore do not recommend reusing the Quickwire method if the wire is ever removed. Best to side wire the outlet instead. The Quickwire hole on the back only accepts a 14 gauge wire because a thicker 12 gauge wire tends to open the spring clamp, causing loose a connection if a thinner 14 gauge were inserted later.

Why would anyone Quickwire an outlet? It’s simple and fast. If time is money and the electrical contractor is squeezing every penny (remember the job went to the low bidder), then backstabbing the wires would be attractive.

Back Wiring: Leviton Screw & Clamp Method

Back wiring the Leviton 5252 series industrial grade electrical outlet is a whole different ballgame compared to the residential grade Quickwire push-in (backstab) system.

The 5252 industrial grade outlets use a screw-and-clamp mechanism which very securely holds the wire in place and equals the reliability of side wiring. Notice in the closeup below how the screw clamp makes positive contact with the wire with a large conductive surface. The clamp also has serrations to bite into the wire for extra holding power. The wire cannot rotate or wiggle.

I prefer back wiring with the screw and clamp system because it’s as secure as side wiring, while being simpler and faster.

In my opinion:

- Side wiring is always good.

- Quickwire push-in (backstab) should be avoided.

- Back wiring with the screw and clamp system is my preference.

Note that all three receptacle wiring methods are listed by Underwriter’s Labs. Check with your local building department if in doubt to comply with all electrical codes.

Hope this helps,

Bob Jackson