A new section of 2×4 lumber is spliced into the load bearing stud, secured with mending plates and cross braces. The drywall repair panel is then installed to close the wall. This project is continued from How to Repair a 2×4 Load Bearing Wall Stud – Part 1.

Load Bearing Wall Stud Splice Repair

The ends of the load bearing 2×4 stud are checked with a square and trimmed with a hand saw to make the ends flat and true. It’s important for the ends of the new splice stud to seat evenly against the existing stud to make an even load bearing surface with no high or low spots.

Next, the vertical gap in the stud is measured and a new board is cut a 1/2 inch or so longer than the gap measurement. The new board is rested on the bottom of the existing stud, the actual length marked with a pencil and sawn about 1/8″ longer:

After a trial fitting and trimming with my DeWALT compound miter saw for perfect edge, the slightly long (1/16″ to 3/32″) splice board is tapped into place with a hammer for a tight fit to restore the load bearing path:

2×4 Splice Stud Mending Plates and Cross Bracing

The splice stud is fastened to the existing stud with Simpson Strong-Tie metal mending plates and SD8 #8 1-1/4″ on both sides of the stud, using four mending plates in all. The mending plates are not rated for load bearing capacity and carry almost no load in this configuration.

Four short horizontal 2×4 braces are attached to the splice stud at the top and bottom of the opening in the drywall. This serves two purposes:

- Bracing for the splice stud

- Provides backing and a ledge to fasten the drywall repair panel with drywall screws.

I attached the 2×4 braces with Simpson Strong-Tie metal angle connectors because I had several available and there was no room to swing a hammer for nailing.

Two vertical 2×4 blocks were attached with wood screws to the studs on the left and right to provide mounting support for the drywall repair panel.

This setup is if anything, over engineered. I grabbed splice stud and worked it back and forth with my 215 lb weight – it was very rigid and strong.

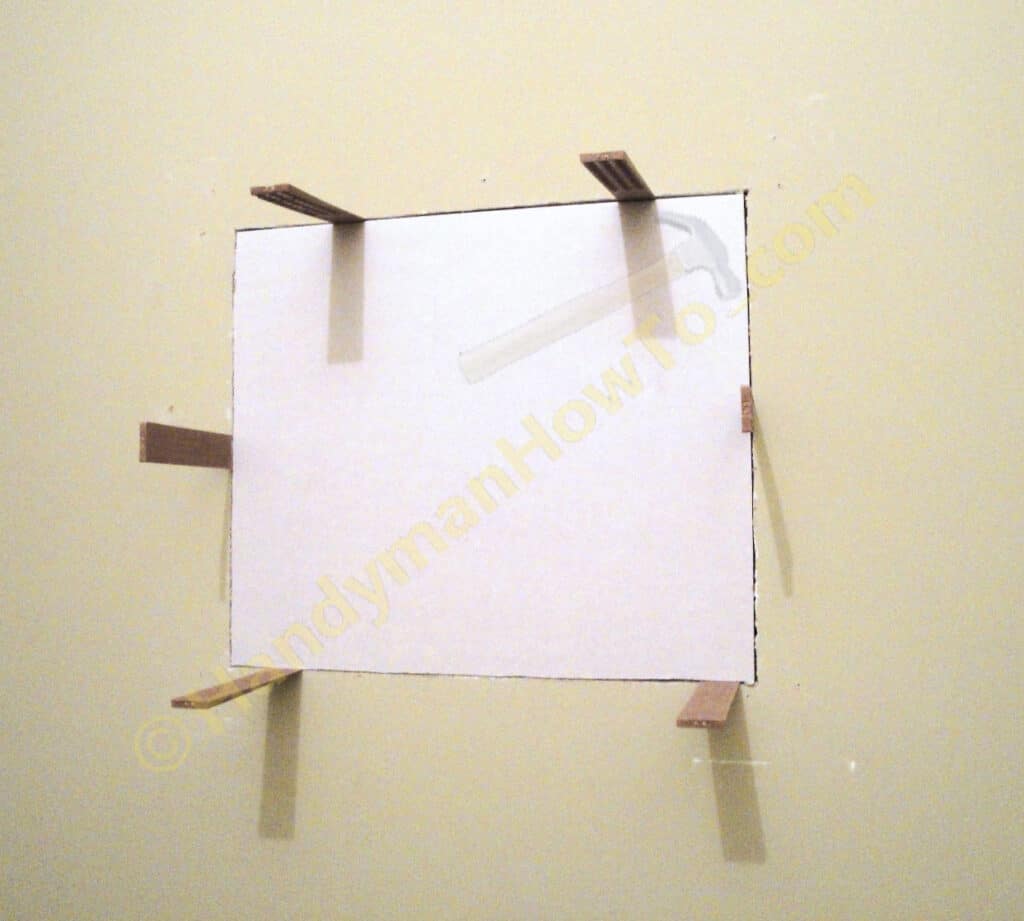

The following photo is from the finished side of the wall. Notice the horizontal 2×4 braces and vertical side blocks are set evenly with the back of the existing drywall so the drywall repair panel will seat evenly with the rest of the wall:

Install the Drywall Repair Panel

The drywall repair panel required some trimming with a utility knife and trial fitting. The panel was adjusted to allow a 1/8″ gap around the perimeter for stress relief and space for the drywall mud. When I was satisfied with the fit, the panel was centered with plastic shims to maintain the 1/8″ gap around the perimeter:

The repair panel is fastened to the 2×4 wood framing with 1-1/4″ drywall screws and a drywall screw setter bit:

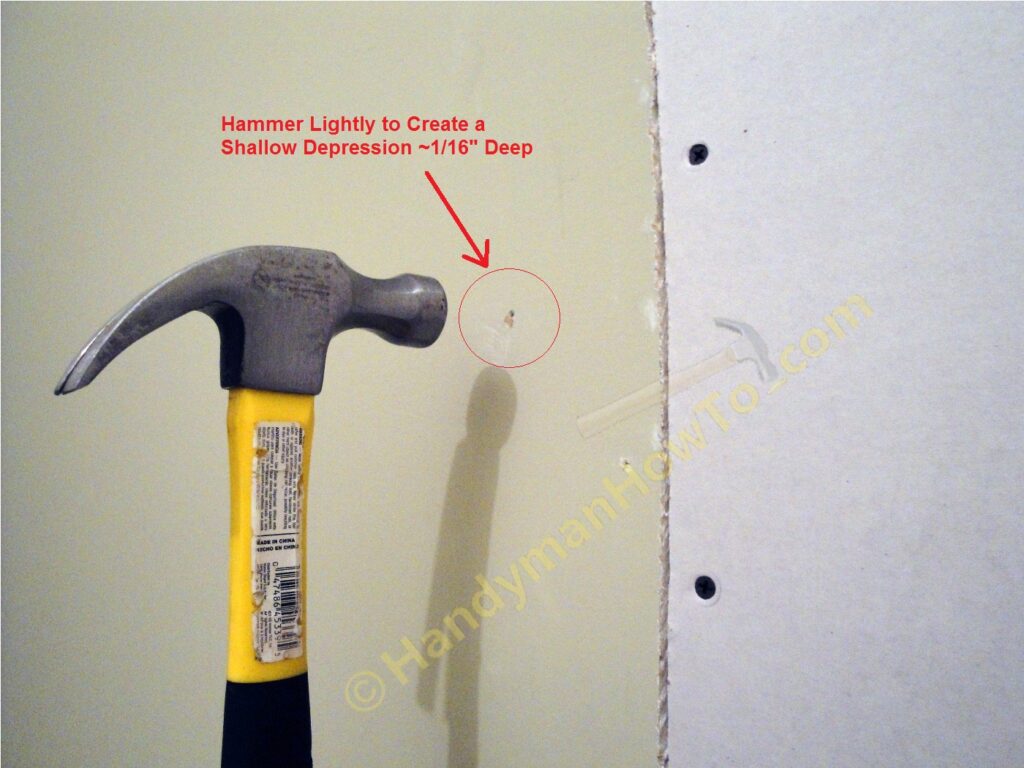

The drywall screw setter bit sinks the screw to the correct depth with small dimple every time. Install screws in each corner and space the screws about 8″ apart (and not more than 12″) on the sides. This is a small panel so my fastener spacing was more like 6″ to make it secure:

The old nail holes from the trim boards are dimpled slightly with a hammer to be filled with drywall mud:

This project is concluded in How to Repair a 2×4 Load Bearing Wall Stud – Part 3.

Hope this helps,

Bob Jackson