The sheet metal mounting plate is fastened to the air handler rigid duct board plenum and the Honeywell UV100A1059 UV light installed. This project is continued from How to Install a Honeywell Ultraviolet Light Treatment System – Part 2.

Air Conditioner Evaporator Coil Inspection

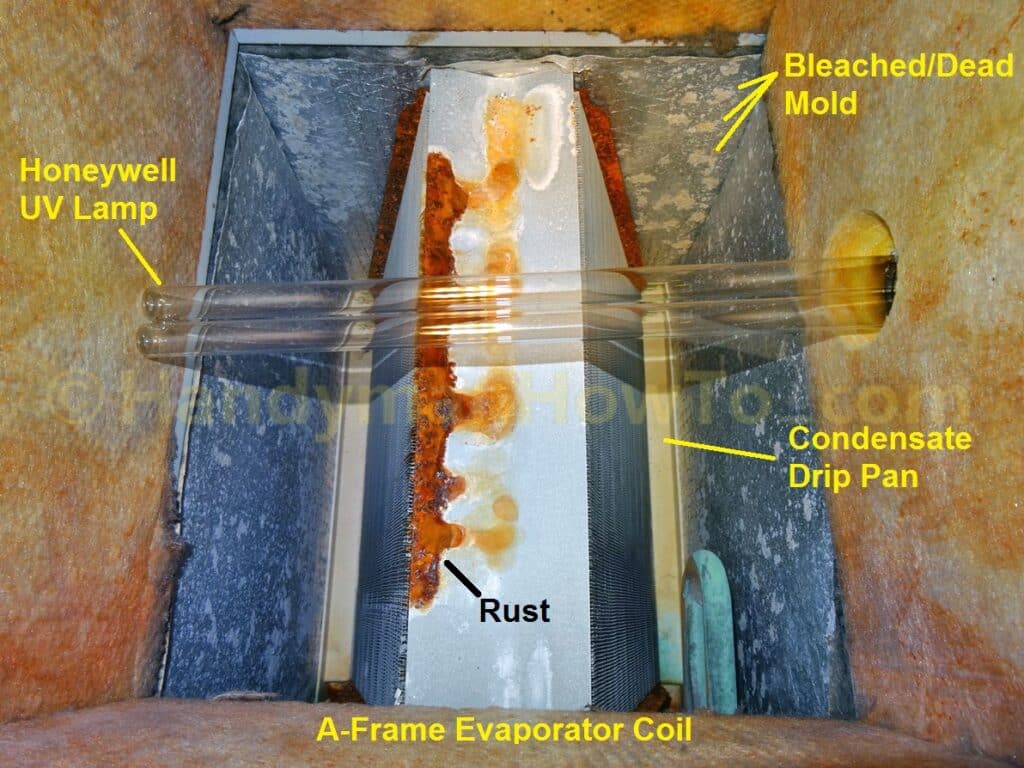

I haven’t opened up the evaporator coil case since last summer and was surprised to find mold had started growing on the foil-faced insulation! (What will they say about me at the garden club?!) There was no odor. Mold appears in a wide range of colors, including white, yellow, brown, black and green so identifying the particular species is difficult. The A-frame evaporator coils looked clean with the usual rust on the coil end plates and some rust stains along the top edge of the coils.

Yuck! Looking closer inside the plenum I found mold growing on the end of the rigid duct board at the bottom of the plenum box. What I believe happened is the edge of the fiberglass duct board tends to filter dust particles from the air stream which provides a food source for the mold.

Below is the opposite side of the evaporator coils and plenum box. Some mold colonies are visible on the foil-faced insulation. The evaporator coils appear clean and the rigid duct board plenum has only a few spots. The 12 inch flexible duct and metal start collar looks fine. Note that UV light will deteriorate the plastic flexible duct liner, causing it to become brittle… more on this later.

I bought the Honeywell UV100A1059 UV Surface Treatment System before I opened the evaporator coil case thinking it would be a nice add-on for my air conditioner. Now I see that I really need it!

Install the UV Light Sheet Metal Mounting Plate

The 1 inch thick fiberglass rigid duct board plenum won’t hold the UV100A1059 mounting screws. The 6 inch x 14 inch 16 gauge sheet metal plate provides hard points for the mounting screws and structural support for the Honeywell UV light by distributing the load across the face of the duct board.

The sheet metal mounting plate is fastened to the duct board with 2 inch wide aluminum foil HVAC tape. Don’t use regular “duct tape” because it won’t last. I used a carpenter’s bubble level to level the plate horizontally and centered it on the side of the plenum. The plenum is 18 inches wide and the steel mounting plate is 14 inch long. I therefore have a 2 inch margin on each end of the plate for the HVAC tape.

Note that the 2 inch hole in the steel plate for the UV lamp is well clear of the evaporator coils; when installed, the UV lamp will be about 3 inches above the A-frame evaporator coils.

Two overlapping layers of aluminum foil HVAC tape are applied to the secure the sheet metal mounting plate to the rigid duct board plenum. Space the layers of HVAC tape as shown to distribute the load across the duct board.

A 2 inch hole is cut in the rigid duct board with a narrow serrated knife, using the sheet metal hole as a guide. Cut the insulation to make a cone-shaped plug (like cutting the top of a pumpkin to make a jack-o-lantern) that is wider on the inside of the plenum. The purpose of the conical shape is to make an air gap between the UV lamp base and the duct board to prevent excessive heat buildup near the UV lamp filaments. Reach inside the evaporator coil case and remove the duct board plug. Trim the duct board as needed so the conical air gap is even on all sides.

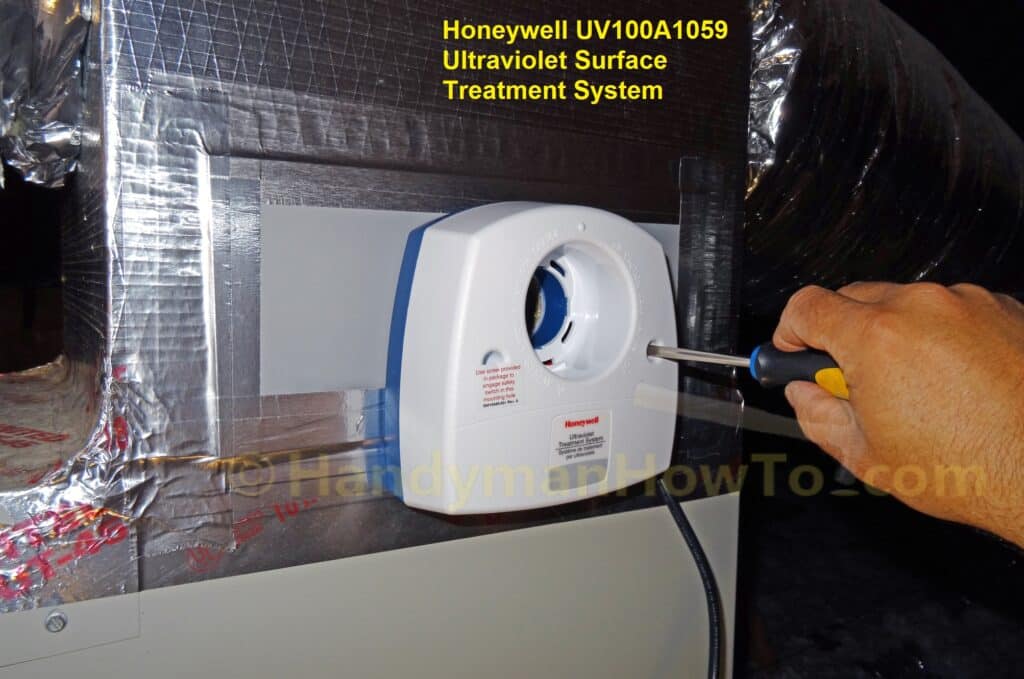

Mount the Honeywell UV100A UV Light

Use a screw driver to fasten the two mounting screws to the sheet metal plate. Be careful not to over tighten the screws because you can strip the threads cut in the sheet metal. I don’t recommend using cordless drill/driver on the screws because it doesn’t provide the “feel” and fine control of doing it by hand.

Try not to touch the glass surfaces of the UV lamp (use a clean cotton cloth to hold it) and wipe down the glass with the cloth to remove fingerprints. Hold the lamp with the lamp indicator light in the UP position (refer to the Honeywell UV100A1059 installation guide for details).

Orient the UV lamp at an 11 o’clock position and insert it into the base unit, then right twist to lock it in place at the 12 o’clock position:

Plug the UV100A power cord into a grounded 110 volt AC wall outlet and don’t look at the light because it will damage your vision. The UV light is invisible, what seen here is blue light that’s close to the UV range in the light spectrum. I took this photo with a camera tripod and timer, then turned off the UV lamp before closing up the evaporator coil case. The UV Lamp Light Indicator on the handle will illuminate to show the bulb is working.

The completed Honeywell UV100A1059 Surface Treatment System installation:

The UV light is connected by an extension cord plugged into a grounded outlet by the attic stairway:

UV Light and Flexible Air Ducts

As noted in Part 1 of this project, UV light will deteriorate the inner plastic liner of flexible air ducts causing it to become brittle, crack and peel. The options for protecting flexible ducts from UV light are:

- If the flexible duct is at least 3 feet away from the UV lamp, the flex duct should be OK and no protection is necessary.

- Choose a UV light which has metal shield so the light only shines in one direction, e.g. downward on the evaporator coils.

Honeywell UV lights don’t offer this option and it wasn’t important to me because I want the UV light to shine in all directions to help prevent mold in the plenum box. -

Attach a metal 90 degree elbow fitting to the plenum box start collar, then connect the elbow flex duct to the elbow.

The 90 degree elbow should provide sufficient UV shielding for the flex duct. An elbow may not be feasible depending on how your ducts are routed. - Replace the standard flex duct with a UV light resistant flex duct product.

ATCO Rubber Products makes a special purpose ULTRA-FLEX Duct Kit made for use with UV bio-treatment lamps. ATCO only sells to distributors and it may be challenging for a homeowner to find the product.

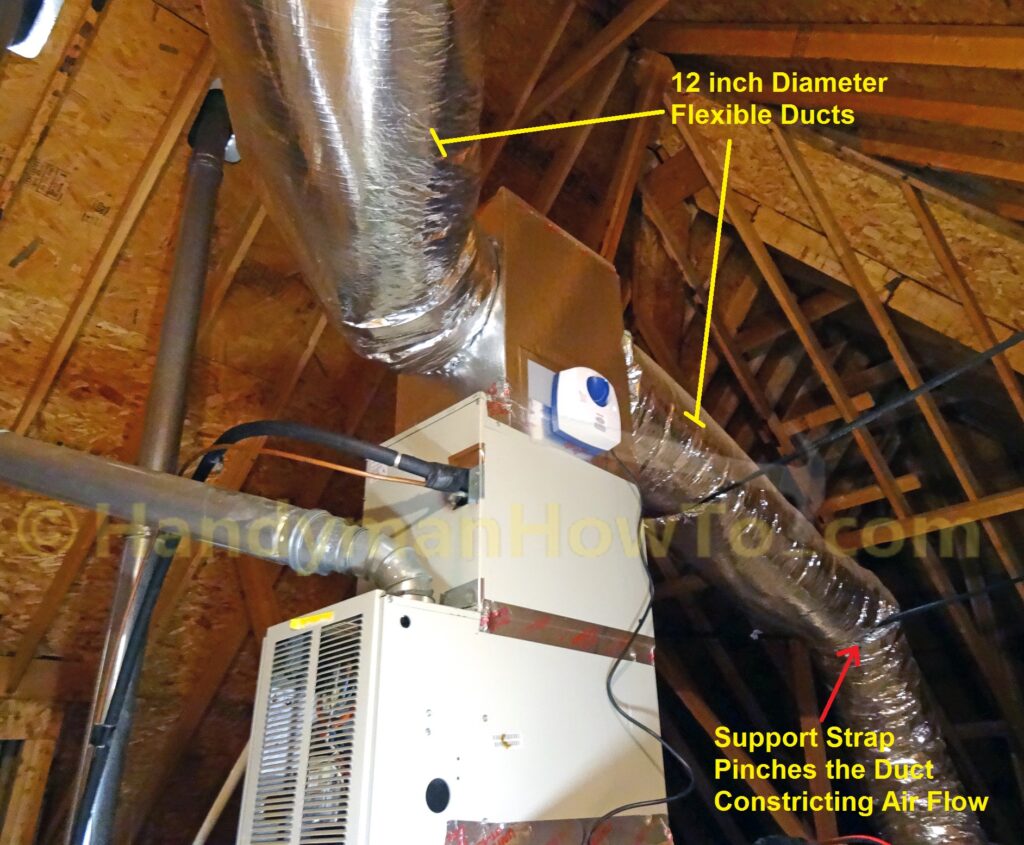

What is my plan to prevent damage my flexible air ducts? Replace the 12 inch diameter flexible ducts with galvanized steel duct pipe and fittings.

The reasons for replacing the plenum flex duct with round metal duct pipe are:

- Flexible ducts are a poor choice for trunk ducts due to friction losses caused by the ribbed inner liner, which reduces the airflow compared to smooth metal duct pipe.

- Flexible ducts if not properly supported will pinch and constrict the air flow (see the above photo at the support strap).

- Metal ducts are not affected by UV light.

- The material cost to replace the two runs of 12 inch flexible duct will be $200 to $250.

- The job is not difficult.

Why are flexible ducts used? Because flex duct is easy and quick to install versus metal ducts. Flexible duct is OK for short runs of branch duct, but not nearly as efficient and durable metal duct. As the following photos illustrate, the low-bid HVAC installer hired by the home builder (who quickly went out of business after my home was built) did a sloppy job installing the flexible ducts.

Flexible Air Duct Installation Errors

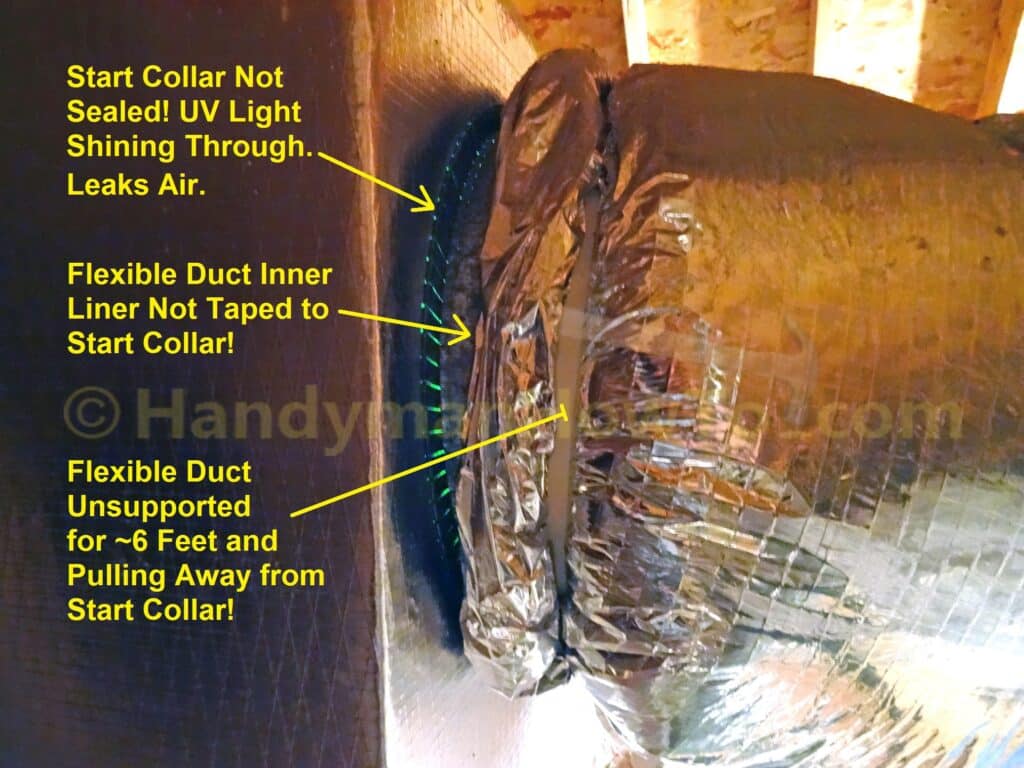

This is the 12 inch flexible duct on the front of the supply air plenum. All kinds of installation problems here:

- The metal start collar is not sealed with mastic (best) or HVAC tape.

Cold air is blowing and UV light is shining through the start collar ribs. - The inner core of the flexible duct is not taped to the start collar.

- The flex duct is pulling away from the start collar because it’s unsupported for over 6 feet.

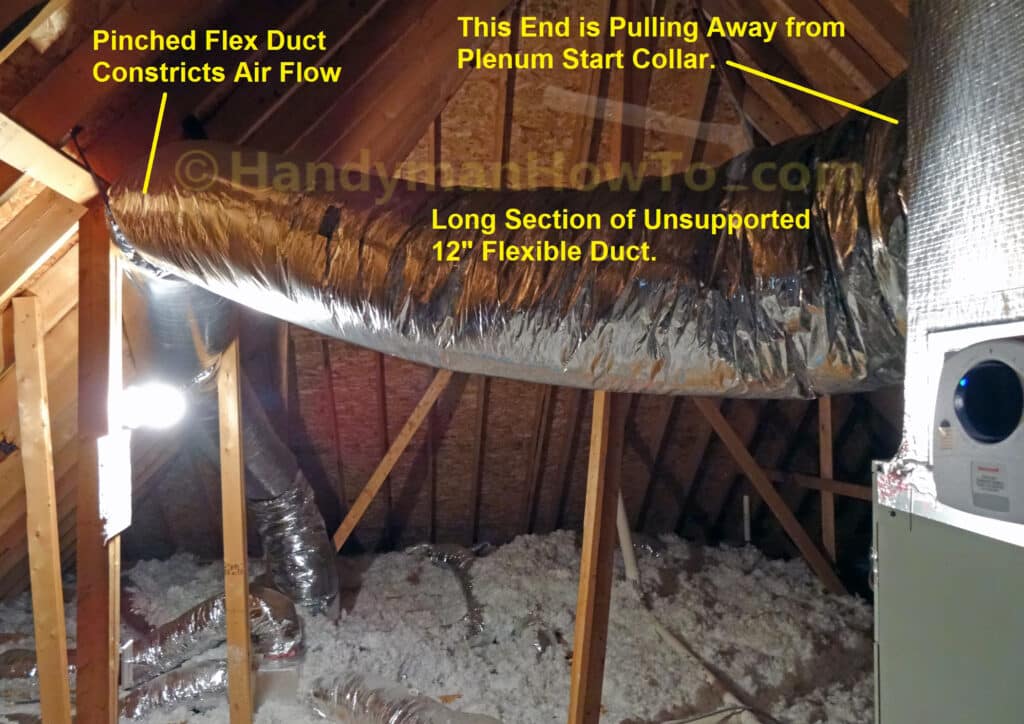

Another view of the flexible duct with the long unsupported span and pinched flex duct at the hanger strap on the left:

I’ll replace the flexible duct with sheet metal.

AC Evaporator Coil UV Lamp Performance

I took this photo several months later while installing the sheet metal air ducts and got a good look inside the supply air plenum above the AC evaporator coils:

Key observations are:

- The Honeywell UV lamp spans both sides of the evaporator coils for maximum irradiation.

- The evaporator coil faces are shiny and clean.

- The condensate drip pan is very clean with no signs of algae or mold.

- There is no indication the UV light has deteriorated or cracked the plastic condensate drip pan.

- The mold blotches on the foil faces of the evaporator coil case insulation are bleached and crusty due to a really bad case of “sunburn” by the UV light.

- The yellow insulation of the supply air plenum ductboard is very clean, almost like new.

- A portion of the yellow ductboard insulation at the lower left and upper right has lifted, exposing it to the air stream. This promoted air filtering which darkened the edges and provided a medium for the mold growth as was seen in the previous photo.

Hope this helps,

Bob Jackson

Hello Bob

I happened upon your site again when I was looking at installing a UV light in my HVAC. I’m happy to see you have a HVAC UV light install guide. Once again, (“I’m not worthy”) thanks for your EdgeRouter site config post back in ~2010. I have now leveraged your original post to help me with a new pfSense config (Boo Ubiquiti for silently abandoning their eEdgerouter line). Boy, we are old. I have a Lennox system (NEVER buy one – There is a class action lawsuit against several manufacturers for poor design materials – don”t quote me – google it!) and I was concerned about UV degredation of the drip pan. I was going to mount the UV light several feet away from the furnace (return air plenum and on one side of a Y’ed return air plenum) to avoid UV degredation of the heat pump coil drip pan. I appreciate your insight and post. I’m wondering if I need to worry about drip pan UV degredation with Lennox. Do you have any non-brand general insight on Drip Tray UV resistance? It would seem to me that UV resistance would be commonplace given the common use of air quality improvement methods (mechanical and electrical).

Once again, your input is appreciated.

Thanks

BTW Bob

Did you install a 45 or a 90 (of course worse) elbow at the pinch point? I don’t want to say something obvious, but a few well placed straps may turn a 45 or 90 into a sweep.

Best regards