This project explains how to replace a leaky toilet water shutoff valve by removing old valve and install a quality Brasscraft G2 Series 1/4 Turn Ball Stop Valve.

How to Replace a Leaky Toilet Water Shutoff Valve

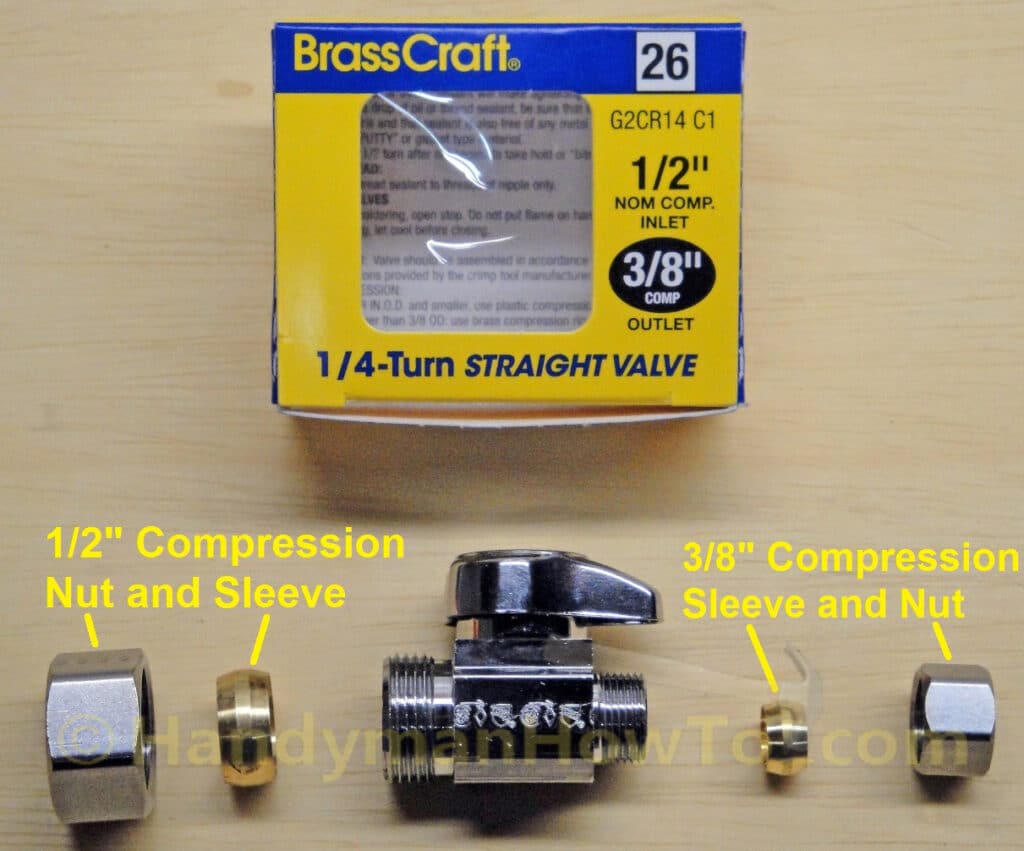

I could have repaired the old multi-turn water shutoff valve by replacing bonnet packing washer by purchasing a repair kit for around $2, however the new 1/4 turn stop valve doesn’t cost much and it’s almost the same amount of work to fix an old valve compared to installing a new valve. The new Brasscraft 1/4 Turn Ball Stop Valve model G2CR14 C1 has a 1/2 inch compression inlet and 3/8 inch compression outlet that fits 1/2 inch copper water pipe:

Water stop valves are also installed on the hot & cold sink faucet pipes. Your stop valve might be an angle stop if the water pipes come out the wall instead of the floor, meaning the 3/8 inch outlet is at 90 degrees to the inlet (i.e. an elbow). The installation steps are the same for both straight and angle stop valves.

I prefer the 1/4 ball stop valve because in my opinion it’s a better design than the multi-turn stop valve for the following reasons:

- Only 1/4 turn to open or close the valve – a nice convenience.

- The ball design positively shuts off the flow of water when closed, and does not obstruct the flow when open.

Compare to the multi-turn stop valve, which is type of globe valve. - Less prone to leakage over due to the ball design and two internal o-rings on the valve stem.

- More durable and reliable.

The Brasscraft G2 series 1/4 turn ball stop valve operation is illustrated in the following sequence, from fully open (left image) to fully closed (right image):

Toilet Stop Valve Compression Fittings

The Brasscraft 1/4 turn stop valve uses compression fittings that consist of a brass sleeve that fits over the 1/2 inch copper tube and 3/8 inch toilet or faucet connector hose (see photo below). The compression nut squeezes the brass sleeve against the tube for a water tight seal. The advantage of compression fittings over sweat (i.e. heat soldered) connections are:

- Requires only basic skills to install, versus the practice needed to learn how to solder a sweat joint with a propane torch.

- No heating with a torch means less chance of overheating the valve body and damaging the plastic & rubber components when soldering a sweat joint.

- Can be installed in cramped spaces where a propane torch would be a fire hazard.

- (Usually) easy to remove with only a wrench if the valve needs replacement.

- Can be installed “wet”, meaning the copper pipe doesn’t not have to be completely dry.

A sweat fitting by contrast can only be soldered when the pipe is dry because any water inside the pipe will absorb heat from the propane torch creating relatively “cold” spots – it only takes a few drops of water to be a problem! The melted solder won’t completely wick into joint with cold spots leaving gaps that will leak. Residual water inside the pipe is often a challenge because you’ll stick a rag in the pipe to soak up the water, only to find a small trickle re-wetting the inside of the pipe due to water backflowing from pipes elsewhere in the house.

I also have installed solder sweat joint stop valves on new plumbing installs when there’s sufficiently long copper pipe stubs to use a propane torch. A sweat joint will practically last forever.

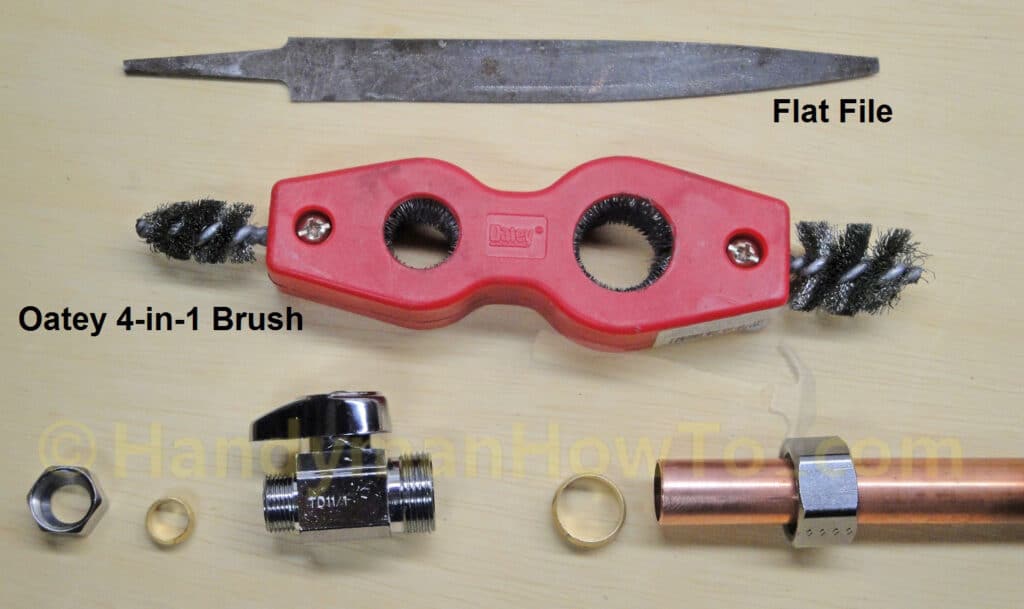

The following tools are needed to replace a water shutoff valve:

- Flat steel file to deburr the inside of the 1/2 inch copper tube; and to bevel the outside edge of the tube.

The end of the copper tube may have a slight ridge made by the cutting wheel of the tube cutter that can make it difficult to insert into the stop valve body. A quick filing will knock down the ridge; just spin the end of the copper tube against the flat file while holding it at an angle. If replacing a stop valve, you won’t need the steel file because deburring and filing have already been taken care of. - 4-in-1 Brush for cleaning 1/2 inch and 3/4 inch copper tubing.

Aside: Small diameter copper pipe is more correctly described as “tubing”.

Water Shutoff Valve Compression Fittings

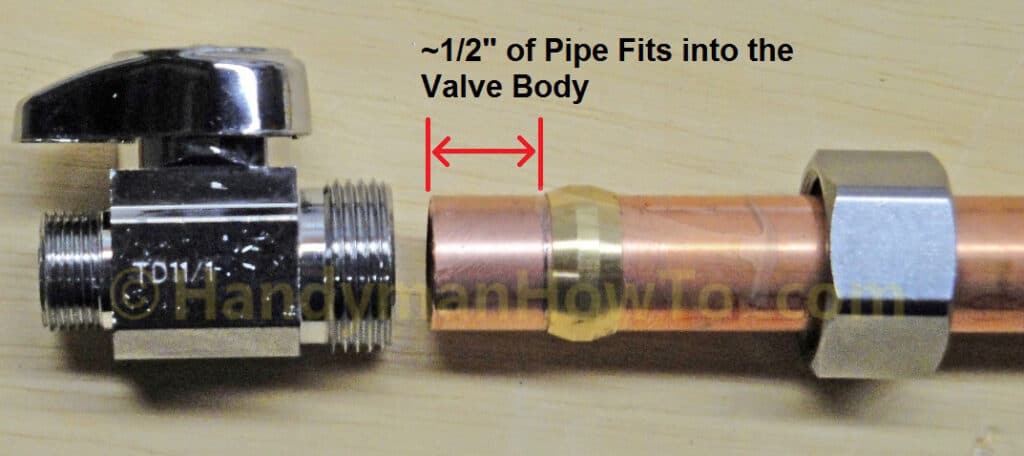

Before replacing the toilet stop valve, let’s take a look at how it installs on 1/2 inch copper pipe.

The water stop valve compression fitting installation steps are:

- Clean the end of the copper tubing with the Oatey 4-in-1 brush. Insert the tube into the brush hole and turn the brush. The brush wires will remove any paint, dirt and oxidation from the outside of the copper tube.

- Slide the compression nut over the tube with the threads facing the end of the tube (i.e. facing the stop valve).

- Slip the brass compression sleeve on the tube about an inch or so. You don’t need to be precise here.

The copper tube will go about 1/2 inch into the stop valve body as indicated in the following photo:

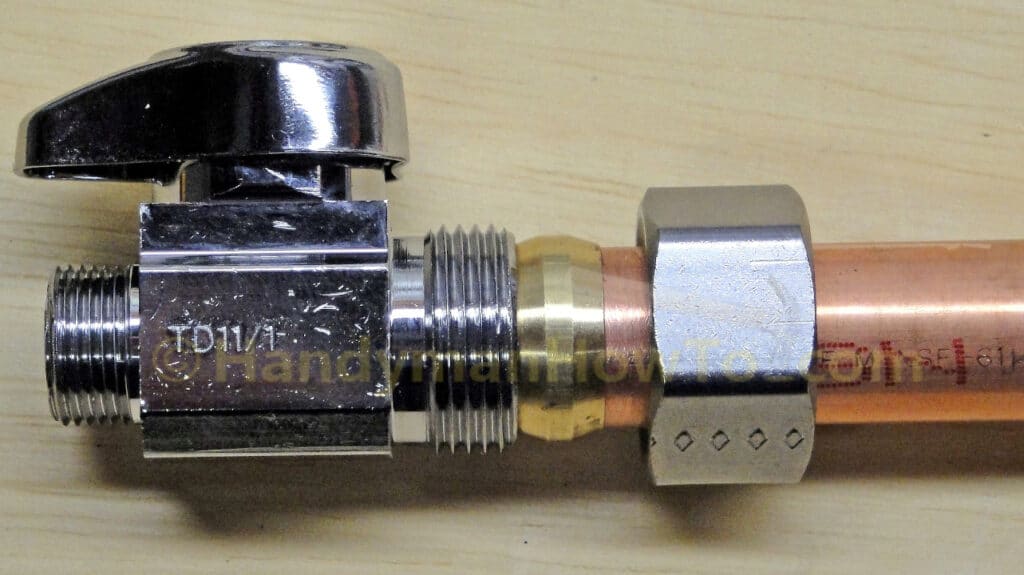

Slide the stop valve onto the end of the copper pipe until it’s fully seated. The valve body should go on easily. You can see how the brass compression sleeve is beveled on both ends and will be squeezed against against the valve body and copper tube to make a water tight seal:

While holding the valve body against the end of the copper pipe, press the compression nut and brass sleeve up to the valve body. Spin the nut on by hand, then tighten the nut with a wrench until you feel it seat (or bite) against the brass sleeve – it’s a distinctive feel, you can’t miss it – then tighten the nut an extra 1/2 turn. Take care not to over tighten the nut because you can crack the valve or nut. You can always tighten the nut a bit more if it leaks.

The water shutoff valve compression fitting system is a simple and reliable system.

This project is continued in How to Replace a Leaky Toilet Water Shutoff Valve – Part 2.

Take care,

Bob Jackson