How to Finish a Basement Bathroom – build the tile shower pan by installing the shower curb, mortar bed, shower pan liner and cement backer board. This project is continued from How to Finish a Basement Bathroom – Part 2. See the series introduction for the project index.

How to Build a Tile Shower Pan

Oately, Inc. has an excellent overview of shower pan construction here and my installation will be identical. The Oatey shower pan video is the best I’ve seen:

The shower curb for the shower pan is built using pressure treated 2×4’s and Tapcon concrete anchors.

If I were to do this over again, I would use pre-formed shower curb and pan products like the Schluter-KERDI-SHOWER-KIT for faster installation and less work. Ask the people at your local tile specialty store for recommendations because the big box home improvement stores often don’t carry these products.

Bags of dry mortar for a tile shower pan bed is mixed in a 5 gallon bucket, then the primary mortar bed is being laid with a trowel and gently sloped for drainage toward the shower drain:

Pre-Pitch Shower Pan Guide Tool

I highly recommend using one of the pre-pitch tools for sloping the shower pan mortar base for a perfect result every time. Also see the Schluter-KERDI-SHOWER-KIT toward the end of this page.

I spoke with several plumbing contractors and most said they skip the pre-slope mortar bed. Rather they install the PVC shower pan liner first and make the mortar bed all at once. Doing so will cause problems with mold and ponding in the permeable mortar because the mortar bed is not waterproof and soaks up water. Something to note if hiring a plumber to build the shower pan.

The pre-sloped primary mortar bed is completed in the following photo:

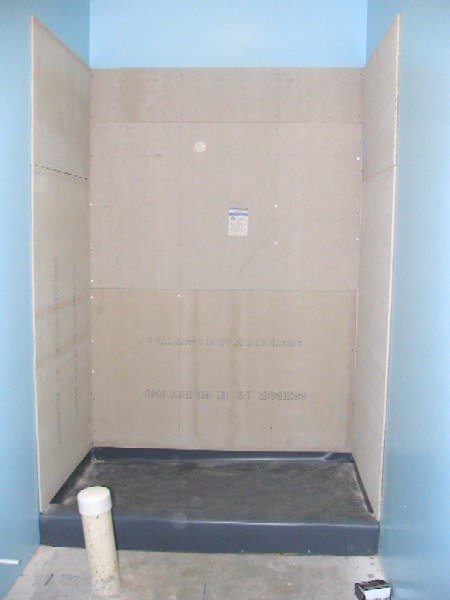

The PVC shower pan liner is installed over the pre-slope mortar bed and about 8 inches up the shower walls (see the following photo). Take care to nail only the top edges of the liner to the walls to keep the shower pan waterproof. I’ve also installed 1/2 inch James Hardie HardiBacker cement board on the shower walls in preparation for laying tile using corrosion resistant screws. A hole will be cut through the PVC liner for the shower drain. For details see the Oatley shower pan liner instructions.

Note: I should’ve installed the cement wall board about 3 inches further down so the bottom edge is about 1/4 inch above the shower pan to cover nearly all of the shower pan liner on the walls (an oversight in retrospect). Doing so would’ve allowed finish layer of mortar to cover the bottom portion of the cement wall board so there’s a continuous solid base for the tile. My job turned out OK because the finish layer of mortar over the pan liner narrowed the gap at the bottom of the cement board and I applied mortar against the walls over the liner. The 6″ x 6″ wall tile was large enough span that bottom gap while mostly supported by the cement wall board.

Metal lath is laid over the PVC liner and tacked to the outside of the curb only so the mortar has something to grip. To make the 90 degree bends for the shower curb, I used a 2×4 and block to make a brake (a “brake” in this sense is device for bending metal). This worked very well with crisp perfect bends.

Another 1-1/2 to 2 inches of bedding mortar were troweled onto the shower pan floor with about 3/4 inch thick layer of mortar over the shower curb. The shower pan strainer is covered with blue masking tape to keep out dirt. The final result is in the photo below. Click on the image for a larger view.

Schluter-KERDI-SHOWER-KIT

I’ve since found a much better and faster way to build a tiled shower base. If I were to build a tiled shower in the future, I’d try the Schluter-KERDI-SHOWER-KIT which features:

- prefabricated, sloped shower tray

- prefabricated shower curb

- thin and lightweight Schluter-KERDI waterproofing membrane that installs beneath the tile and over the shower tray.

This eliminates the possibility of water soaking into the mortar bed as used with traditional shower bases as I’m building here. - prefabricated waterproofing membrane corner pieces

- prefabricated fittings with rubber grommets for the shower head and valve.

- easy to install and big time saver

The porcelain tile shower plans and materials list are figured in How to Finish a Basement Bathroom – Part 4.

Thanks for reading.

Bob Jackson