How to clean AC evaporator coils with no-rinse spray foam cleaner for routine seasonal maintenance. If you’re not comfortable cleaning the AC evaporator coils yourself at least you’ll what’s needed when calling a Heating, Ventilation and Air Conditioning (HVAC) professional.

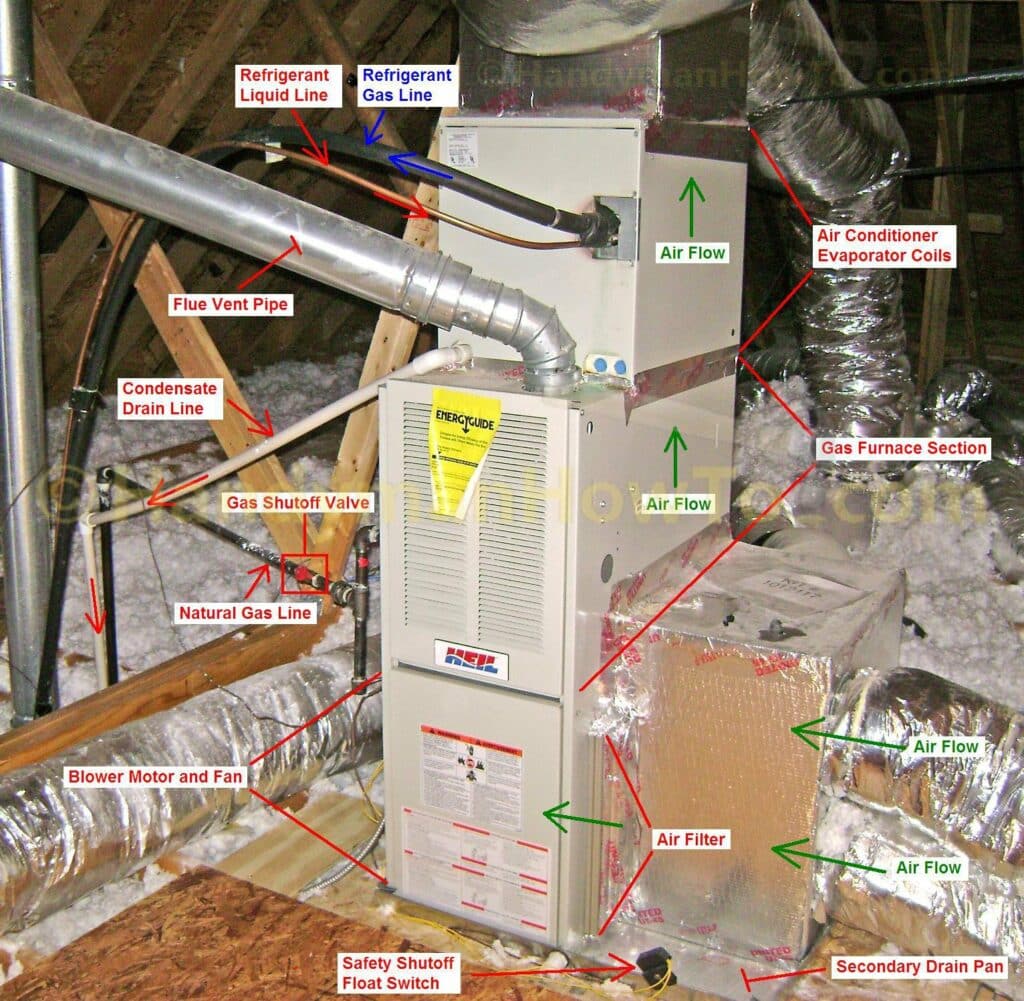

AC Air Handler Components

The following photo is the central air handler in my attic. It is known as an “upflow” type because air enters from the bottom and exits out the top.

The unit combines a natural gas furnace and an air conditioning evaporator coil. It has three major sections:

- Blower motor – bottom

- Gas furnace – center

- A/C evaporator coil – top

The entire air handler sits on a secondary drain pan with a cutoff float switch. The purpose of the secondary drain pan is catch water in case the condensate drain line becomes clogged or the main condensate pan rusts through. The secondary pan will catch the water and eventually activate the float switch to shut down the entire unit before it overflows and ruins the ceiling.

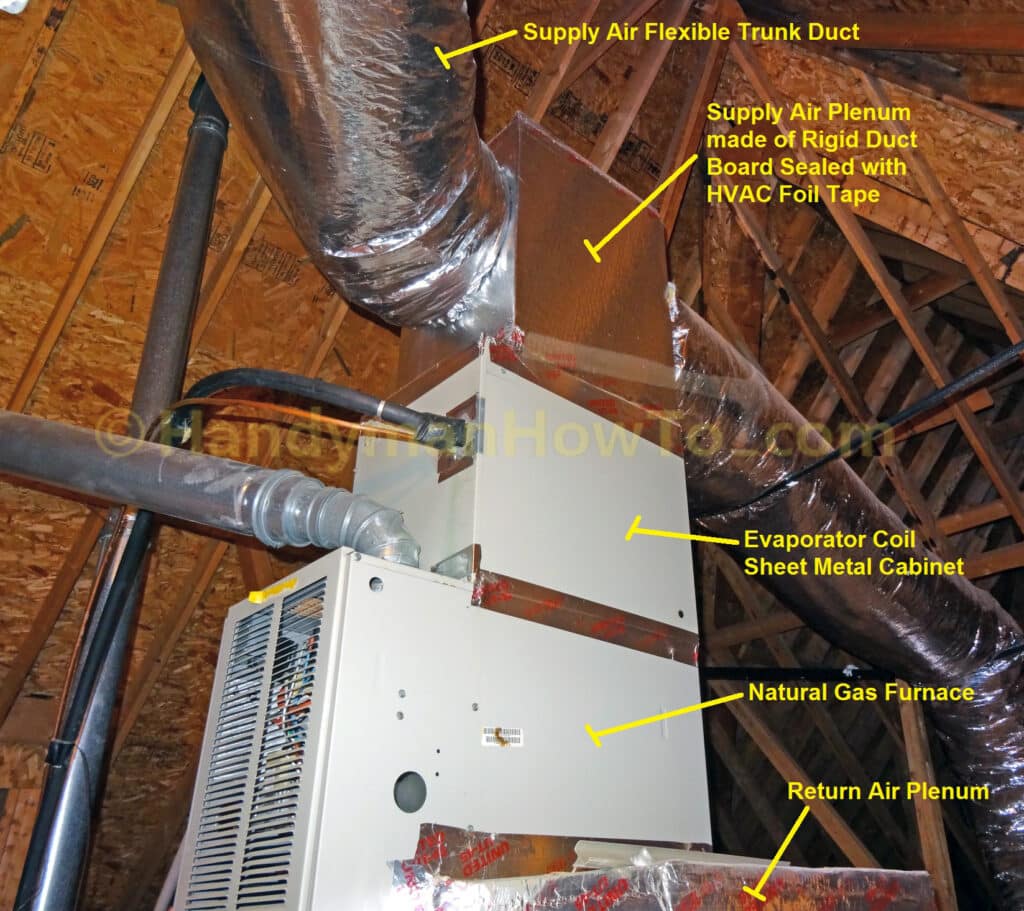

The blower motor forces air upward (recall my air handler is an “updraft” or “upflow” type) through the furnace and air conditioner evaporator coils. The Heat and Cool functions of the thermostat ensure that either the furnace or the air conditioner operate, but never both at the same time. The supply air plenum box sits on evaporator coil sheet metal cabinet. Two large flexible ducts are connected the plenum box. The large trunk flex ducts connect to rigid duct board distribution trunk ducts that lay on the attic joists. Several smaller flexible duct branch lines are taken off the rigid trunk duct to supply air to vents throughout the house.

Update: The compressor was failing on the 17 year old AC system. I had the entire central air conditioner and furnace replaced with a Bryant Evolution high efficiency system. The new Bryant system is blows so much colder and reduced my electric bill by 20%.

How to Clean AC Evaporator Coils

Before you begin, turn off the air conditioner at the thermostat and shutoff the electricity to the air handler. There should be a toggle switch (it will look like a light switch) by the air handler to turn off the power. If not then shutoff the electricity at the circuit breaker panel.

The evaporator coil access panel must be removed to access the coils. This is a closeup of the evaporator coil access panel, which is fastened with nine 1/4 inch sheet metal screws and sealed along the bottom with metal foil HVAC tape.

Remove the access panel screws with a socket wrench and peel away the metal foil tape along the panel edges (if any).

The access panel is removed exposing evaporator coils:

My system has an A-Frame style coil with a removable end plate. Your unit may have an N or slab coil which can be more challenging to access for cleaning. The evaporator coils are basically a heat exchanger, cooling the air inside the house and transferring the heat to the outside condenser unit.

AC Evaporator Coil Inspection

The following is a photo of my central air conditioner evaporator coils before cleaning. The AC coils look very clean already because I service my system regularly. Of some concern is the rust on the ends of the frame. The unit is about 9 years old and rust is common in these areas. The greenish/whitish discoloration on the copper refrigerant lines is from dissolved copper deposits that have dried. The plastic drain pan looks in good condition with no cracking or leaks. Overall, not too bad for a 9 year old evaporator coil. I should expect to replace the coil and/or air handler in a season or two as it approaches the end of its expected life.

Evaporator Coil Icing & Freezing

If your coils look clean but are freezing over, it may be caused by:

- Clogged air filter.

A clogged filter can restrict the air flow through the coils causing condensate water to freeze on the coils. Coils need a large volume of warm air flow to stay above freezing. This is a vicious cycle because the ice grows blocking more of the surface. - Clogged interior coils.

The exterior coils may appear to be clean, but the interior surface can be dirty. The interior surface is on the upwind side (closest to the blower motor) where dust, dirt, pet hair, loose insulation and such will stick. See Heavy Duty AC Evaporator Coil Cleaning for how to inspect the interior side of the coils. - Refrigerant Leak

AC systems can leak refrigerant through failing brazed joints, pin hole leaks cause by corrosion, bad gaskets, etc. resulting in a low refrigerant charge. A low charge will cause the temperature of the liquid refrigerant flashed to a gas through the expansion valve to be much colder than normal causing them to freeze. The gas is much colder because there’s not enough of it to fill the coils; the gas over-expands inside the coils, resulting in lower pressure & lower temperature, hence freezing. The Joule Thomson Effect (highly technical) describes the process. These N style evaporator coils are freezing over, starting at the bottom closest to the expansion valve. An HVAC tech found the coils to be about 2 lbs low on R-22 refrigerant:My AC coils in this project were slowly leaking, needing a recharge of about 1 lb of R-22 per season. They didn’t freeze but the system grew less efficient and the air blowing from the vents wasn’t as cold as it should be

Air Conditioner Evaporator Coil Cleaner

I purchased a can of Frost King Air Conditioner foaming no-rinse coil cleaner:

Nu-Calgon Evap Foam No-Rise Coil Cleaner

The Nu-Calgon Evap Foam no-rinse coil cleaner is specifically formulated for cleaning air handler evaporator coils and approved for use in and around food processing areas. I like the Nu-Calgon Evap Foam because the manufacturer’s page (previous link) includes directions and literature. I used a similar Nu-Calgon coil cleaner in the Heavy Duty AC Evaporator Coil Cleaning project.

Clean the AC Evaporator Coils

The foaming coil cleaner is sprayed directly on the AC coils, coating the surfaces evenly and thoroughly. It’s best to do this on a warm day when the AC will be running to help rinse the coils with condensate water.

The spray foams nicely on the coils.

The no-rinse foam cleaner breaks down and liquifies quickly for a good rinsing action.

In minutes the foam is rinsing itself off and draining away. Always check the PVC drain line is free of algae and unclogged. I poured a quart of 50/50 solution of household bleach and water in the drain pan to keep the line clear. You can also buy time-release algae tablets to drop in the drain pan.

The evaporator coil access panel is reattached with the sheet metal screws. The top and bottom seams are then sealed with HVAC metal foil tape:

Take care not to tape over the manufacturer’s label on the access panel because the service technician may need this data:

The attic AC air handler is now ready for another hot summer of cooling. The last task is to turn on the thermostat.

HVAC Air Handler Basics

Now you’re familiar with the basic components of the attic air handler and the importance of changing the air filter and performing routine system maintenance. If your AC system needs professional servicing, you’ll know what the HVAC technician is talking about. Annual Service Contracts are available from HVAC companies and usually cost less than the sum of ad-hoc maintenance calls.

Heavy Duty AC Evaporator Coil Cleaning

The Heavy Duty AC Evaporator Coil Cleaning tutorial explains how to inspect and perform a heavy duty cleaning which is best for cleaning really dirty coils:

AC Condenser Coil Cleaning

It’s equally important for the outdoor AC condenser coils (also called “compressor coils”) to be clean for proper air flow and heat exchange. The fins on my condenser coils were also badly bent. That project is explained in How to Clean and Straighten AC Condenser Coils.

Stay cool!

Bob Jackson