Adjustable elbow alignment and fitting the last section of sheet metal duct pipe. This project is continued from How to Install Round Sheet Metal Duct – Part 3.

Sheet Metal Air Duct – Elbow Alignment

Instead of a single 90 degree elbow, I’m installing two adjustable set at ~45 degrees for better air flow efficiency per my HVAC ductwork diagram. (90 degree elbows create a lot of air friction because the air has to stop and change direction.)

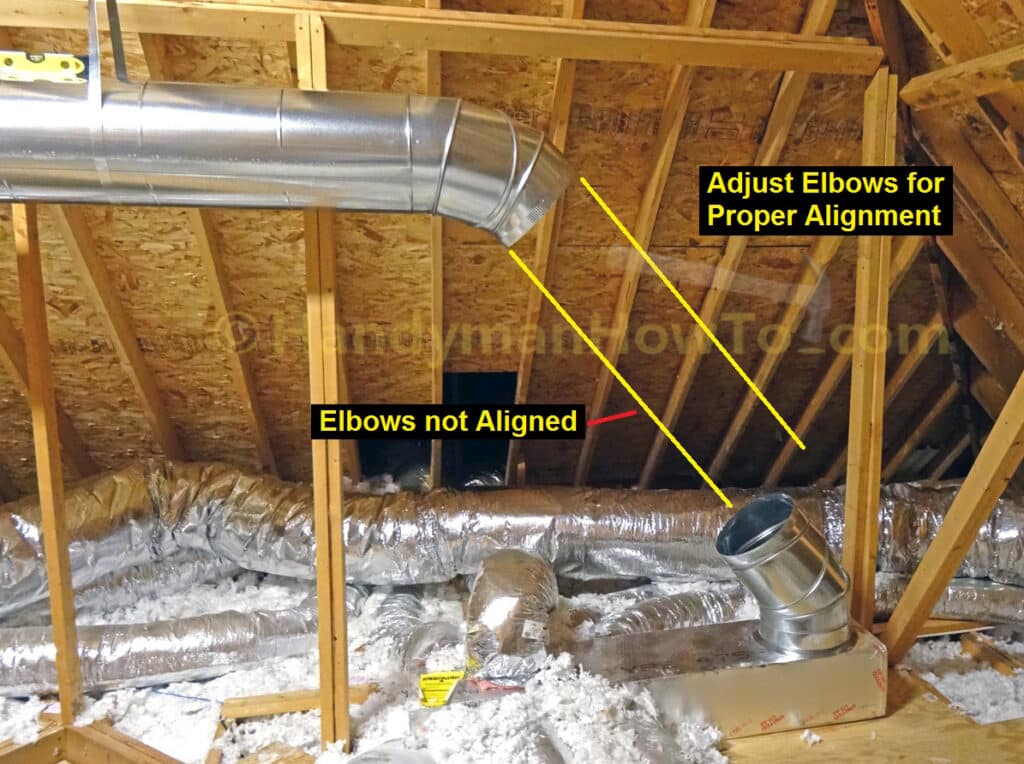

I turned the segments on the upper elbow to what I estimated is the correct angle and attached it to the round duct pipe with sheet metal screws. As illustrated by the yellow lines in the photo, the two elbows were a bit out of alignment:

While a helper held the base of the each elbow, I turned the knuckles (or segments) a little at a time to align the two parts, then rechecked the alignment by laying the edge of a 5 foot aluminum ruler against the elbow the top and sides. When the ruler lays flush against both elbows, the alignment is nearly correct:

And verify the lower elbow for alignment:

Install the Round Sheet Metal Duct Pipe

After aligning the elbows using the 5 foot aluminum ruler, I measured the distance between the two elbows and added 3 inches to allow for the two 1-1/2 inch wide crimp bands on each elbow. Recall the duct pipe will slide over the two crimp bands.

I needed a 52-1/2 inch section of duct pipe to span the two elbows, which is less than the 60 inch (or 5 feet) standard pipe length. See How to Cut and Assemble Snap Lock Duct Pipe for details.

The duct pipe fits together easily without forcing when the elbows are perfectly aligned. I was able to get the elbows closely, but not precisely aligned with the 5 foot aluminum ruler. To fit the last section of 12 inch diameter duct pipe:

- I fit the lower right end of the duct pipe into the elbow at the duct board trunk.

- My helper raised the upper elbow and duct pipe a couple of inches for clearance.

- Then the upper end of the new duct pipe was maneuvered to fit together with the elbow.

The first two attempts to fit the last section of duct pipe wasn’t successful because the upper elbow needed minor adjustments. Eyeball the problem, set the duct pipe aside, adjust the elbow angle by turning a knuckle and try again. As I mentioned, the pipe and elbows fit together easily when precisely aligned. The fitting process took about 5 minutes.

Panoramic view of new sheet metal air duct from the air handler to the rigid duct board distribution trunk. That’s nice looking ductwork!

The lower elbow has just been sitting on the start collar so I could remove it for angle adjustments. I now fastened by driving three self-piercing #8 x 1 inch hex head sheet metal screws equally spaced around the duct through the crimp band. You can feel when the screw pulls the crimp band tight against the outer metal duct as the resistance suddenly increases.

It doesn’t really matter if the duct pipe is level as far as air flow is concerned. I checked the various sections with a magnetic spirit level for two reasons:

- neat installation appearance

- to be sure I hadn’t disturbed the duct while installing the new sections, possibly stressing a joint

The sheet metal duct joints are sealed with mastic in the How to Seal Sheet Metal Air Duct with Mastic.

Hope this helps,

Bob Jackson