How to insulate round sheet metal air duct with R-8 thermal insulation sleeve – sealing the insulation butt joints. This project is continued from How to Insulate Round Sheet Metal Air Duct – Part 1.

Sheet Metal Duct Insulation Sleeve: Start Collar

I began at the supply air plenum start collar and worked my way along the ductwork to secure and seal the insulation sleeve.

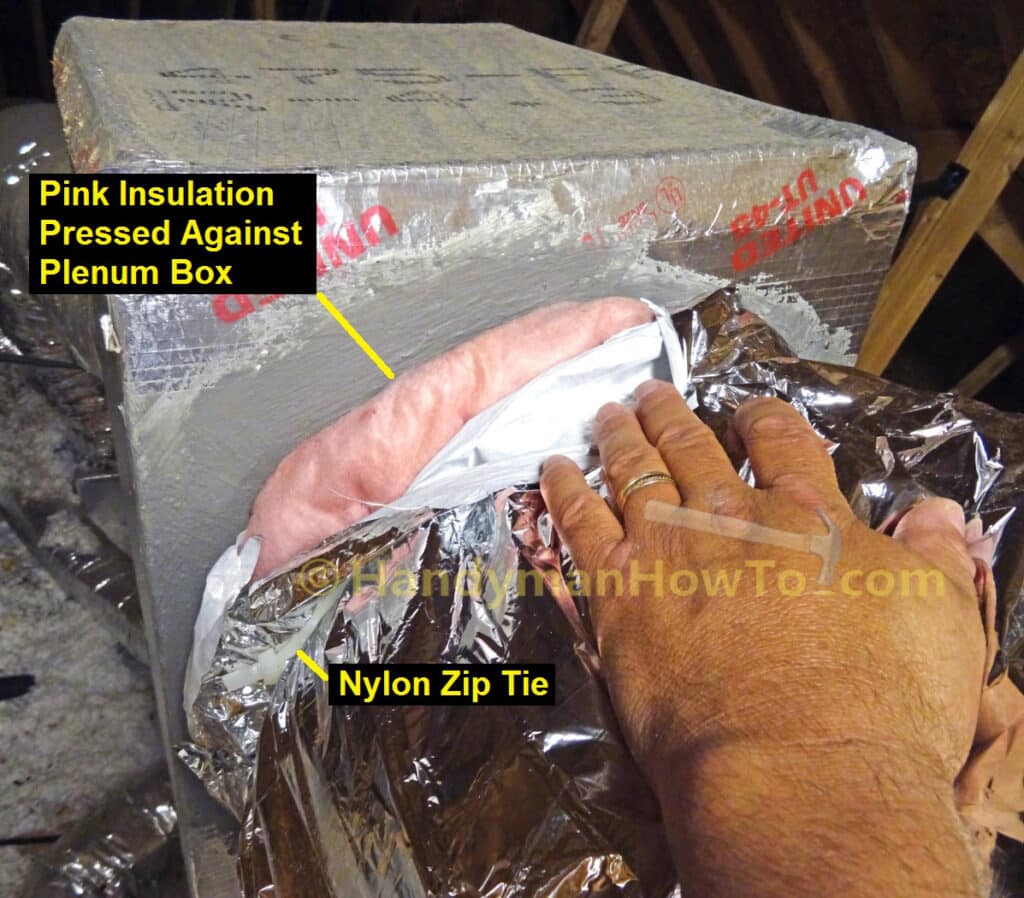

The duct insulation sleeve is extended over the start collar against the duct board plenum, then secured with a nylon zip tie:

I’ve pulled back the foil vapor barrier to show how the fiberglass insulation is butted against the duct board plenum such that sheet metal duct and start collar are fully insulated:

Insulation Sleeve Butt Joints

The insulation sleeve butt joints (or inline joints) are made by pushing together two sections so the fiberglass insulation faces meet…

overlap the foil vapor barriers…

then secure and seal the butt joint with two wraps of metal foil HVAC tape:

Smooth the tape to seal all wrinkles against the foil duct insulation.

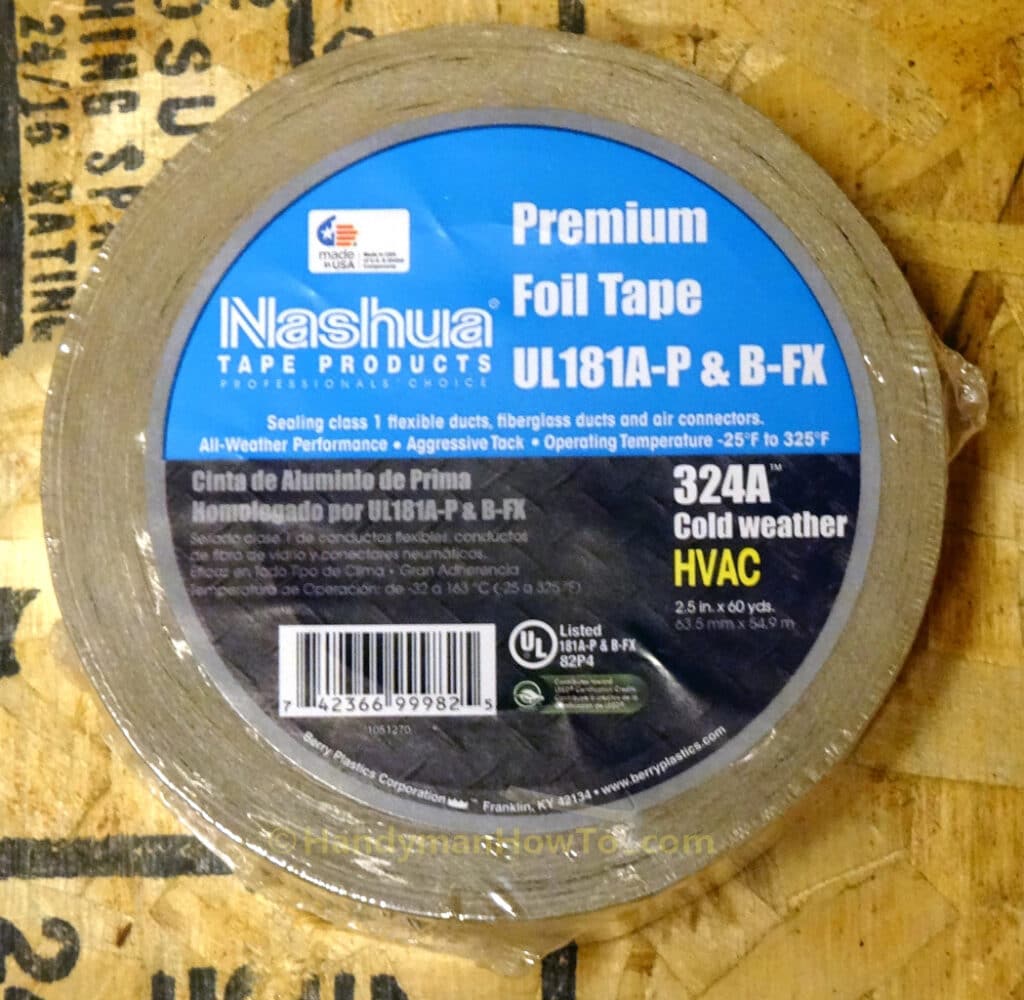

I used Nashua 324A Cold weather metal foil HVAC tape with UL181A-P and B-FX ratings:

Wide angle view of the insulated sheet metal duct:

Installation Tips:

- The duct insulation sleeve should be a bit baggy or wrinkled for maximum R-value rating.

Do not pull stretch the insulation tight because it will compress the fiberglass insulation reducing it’s effectiveness. - The metal duct support straps are looped outside the insulation.

- If the metal duct support strap is in direct contact with the sheet metal duct it will become a thermal conductor, meaning the strap will get warm or cold when running the furnace or air conditioner. A cold strap can cause condensation, dripping water and possibly mold.

- The duct straps were lowered slightly to allow for the insulation thickness to keep the duct aligned with the start collars and avoid stressing the duct board. The duct straps are fastened with screws to the rafters so it was a simple task to lower one side of the strap.

Sheet Metal Duct Support Straps

The International Residential Code (IRC) requires that sheet metal ducts shall be supported at “intervals not exceeding 10 feet“. Most local building codes are adopted from the IRC.

My ductwork is about is about 23 feet in length and I initially installed three 1 inch wide 26 gauge sheet metal support straps, which met the building code requirement for not more than 10 feet between duct supports. I decided to install a 4th support strap at the last elbow to better support the last section of duct pipe:

View of the finished sheet metal duct installation job looking back toward the air handler:

Looking up from the attic stairway at the completed ductwork installation. The job would have been much more cumbersome without the attic shop light.

I took this photo while replacing the flexible duct on the other (bottom of photo) side of the air handler… I was high on the ladder installing duct support strap:

Thanks for reading,

Bob Jackson