How to seal sheet metal duct with mastic to prevent air leaks. This project is continued from How to Install Round Sheet Metal Duct – Part 4.

How to Seal Sheet Metal Duct with Mastic

Sheet metal duct seams and joints must be sealed with mastic to prevent air leaks. The materials for sealing sheet metal duct are:

- Mastic – 1 gallon bucket of Duct-Seal 321.

- 3 inch self-stick fiberglass mesh reinforcing tape for large joints.

- 3 inch wide mastic brush – a soft-bristle short brush.

- Scissors for cutting the fiberglass tape.

- Zip lock sandwich bag for storing the wet mastic brush for reuse.

Mastic vs Metal Foil HVAC Tape

Mastic is a permanently flexible, indoor and outdoor rated, gap filling sealant that sticks to sheet metal, foil faced insulation, wood and most materials. Because it’s a gooey (like peanut butter) brush-on product, mastic conforms to any shape and contour. For long term duct sealing mastic is superior to metal foil HVAC tape. UL181B-FX metal foil HVAC tape is widely used for sealing air handlers, flexible duct and duct insulation wrap, however HVAC tape should be periodically inspected and replaced if loose.

I always use metal foil HVAC tape for sealing the air conditioner evaporator coil access panel and air filter slot because the access panel or filter needs to be removed for servicing.

Mastic Sheet Metal Duct Sealing: Fiberglass Reinforcing Tape

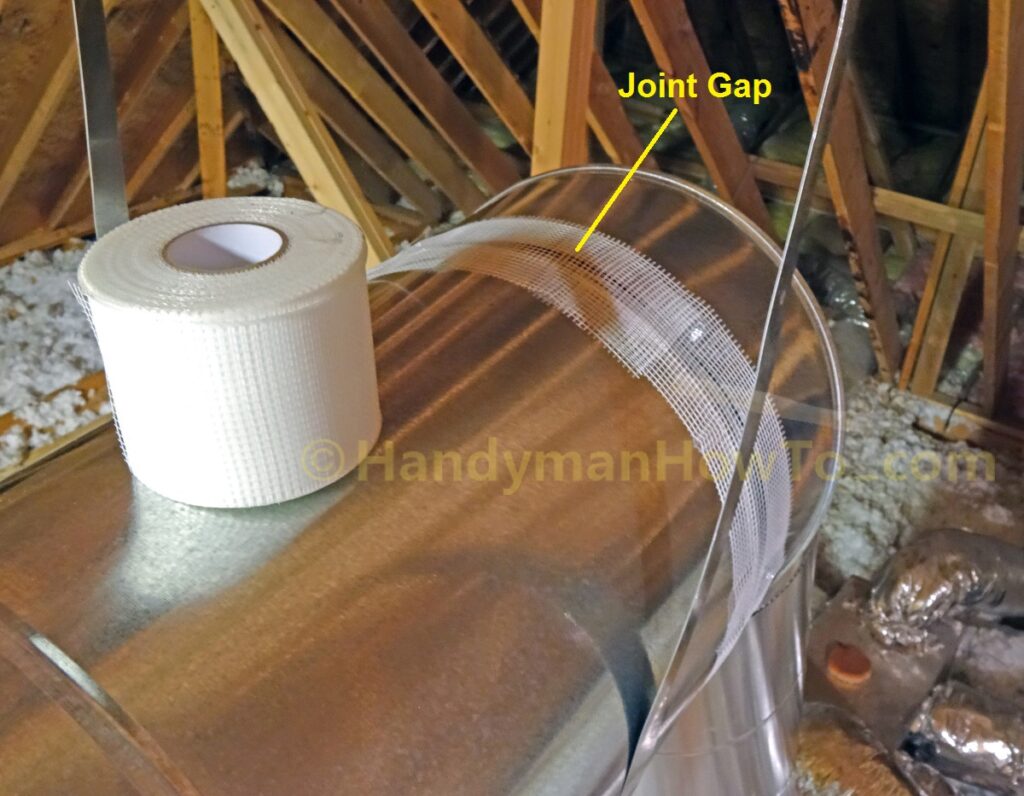

Fiberglass mesh reinforcing tape is needed to support the mastic across larger gaps, such as here where the start collar meets the duct board plenum. This fiberglass tape for sealing HVAC ducts with mastic, do not use fiberglass tape made for drywall joints.

Scissor cuts are made about half-way through the 3 inch wide self stick fiberglass tape so it will wrap around the start collar and lay flat against the plenum. Take care the surfaces are clean, oil and dust free before applying the tape and mastic.

Fiberglass tape is also applied to the far end start collar and duct board distribution trunk duct:

Fiberglass tape is applied to all gaps more than 1/8 inch wide. The 12 inch round duct pipe crimp band was bent a little where it fits into the elbow causing a noticeable gap in the duct joint. After fastening the duct with sheet metal screws, I wrapped the joint with fiberglass tape before applying mastic. Mastic will be worked through tape to fill the joint. This photo was taken when I was replacing the 2nd run of flexible duct on the other side of the air handler:

The Carlisle Duct Seal 321 mastic is a thick, gooey water-based product with very low odor:

Brush on the mastic, working it into the joints and fiberglass mesh. I applied two coats of mastic here, waiting for the first coat to dry before applying the second coat.

Seal all sheet metal duct joints with mastic. I did not seal the 12 inch diameter duct pipe joint with mastic at this time because it will be disassembled after the mastic dries to install the duct insulation sleeve.

The start collar, elbows and snap lock pipe seams are sealed with mastic. The straight duct pipe joints at the elbows will be sealed after the pipe is dissembled to slip on the R-8 insulation sleeve. (If you’ll be installing the wrap around rolls of duct insulation, then go ahead and seal all pipe seams with mastic now.)

Round sheet metal duct sealed with mastic:

View of the mastic and ductwork from the attic stairway:

Next up: Install the duct insulation sleeve and final duct sealing with mastic.

Thanks for reading,

Bob Jackson