This tutorial explains how to add a room air duct for heating and cooling by installing a flexible air duct and vent for better air flow.

Room Heating and Cooling Problem

My daughter’s bedroom was too warm in the summer and too cold in the winter because it had just a single air duct from the central heating and air system. By comparison, my son’s bedroom is about the same square footage and has two supply air ducts that keeps it comfortable year round.

I solved the problem by installing flexible duct branch line and second air vent in my daughter’s bedroom:

Air Handler and Duct Work Problems

A large number of residential Heating Ventilation and Air Conditioning (HVAC) systems are poorly designed and/or installed. The problems I’ve found in my home are:

- Blown fiberglass insulation (the white fluffy stuff that looks like cotton) was piled up near the scuttle hole entrance in the attic over my daughter’s bedroom and the far side of the attic had little or no insulation. Proper insulation is essential for climate control.

- Dirty AC evaporator coils. Dirty air handler evaporator coils will block the air flow, decrease system efficiency and run up your electric bill.

- Dirty or clogged air filter. Change the air filter regularly because a dirty filter will block the air flow.

- Pinched, loose or disconnected flexible air ducts have a huge impact and waste energy.

If you have any of the above problems with your central air system, try fixing those problems first.

Residential Ductwork Projects

I’ve made extensive improvements to my home’s ductwork – adding new air vents and branch lines, replacing flex duct with sheet metal and installing return air pathways:

- How to Add an Air Duct to a Room (you are here).

Ductwork materials and cut an opening in the drywall ceiling. -

How to Add an Air Duct to a Room – Part 2

Install the vent boot and start collar. -

How to Add a Room Air Duct with Speedi-Boot

Easy to install, self-sealing vent boot. -

How to Add a Room Air Duct with Speedi-Boot – Part 2

Plan the air duct branch line and saw an opening in the drywall ceiling. -

How to Add a Room Air Duct with Speedi-Boot – Part 3

Mount the Speedi-Boot and connect the new air duct. -

How to Install an Air Duct in a Suspended Drywall Ceiling

Speedi-Boot installation in a finished basement ceiling. -

How to Install an Air Duct in a Suspended Drywall Ceiling – Part 2

Connect the flexible duct branch line. -

How to Install Round Sheet Metal Duct

Replace central AC flexible trunk ducts with round sheet metal duct for better efficiency. -

How to Install Round Sheet Metal Duct – Part 2

Plenum start collar and adjustable elbow. -

How to Install Round Sheet Metal Duct – Part 3

Metal support straps and snap-lock duct pipe. -

How to Install Round Sheet Metal Duct – Part 4

Adjustable elbows and rigid duct board distribution box connection. - How to Cut and Assemble Snap Lock Duct Pipe

- How to Seal Sheet Metal Duct with Mastic

- How to Insulate Round Sheet Metal Air Duct

- How to Insulate Round Sheet Metal Air Duct – Part 2

-

Bryant Evolution AC Condenser and Ductwork Installation

Replace rigid duct board distribution boxes with round sheet metal duct. -

Tamarack Perfect Balance In-Door Return Air Pathway Review

Easy to install return air grill in a bedroom door.

How to Add an Air Duct to a Room

Speedi-Boot – A Faster and Better Way to install a new air vent. Please see this newer project for a faster and better way to install a room air vent using Speedi-Boot.

The remainder of this article explains how to install an air vent using a conventional vent boot.

The materials for the six inch diameter branch line cost about $60 at Home Depot:

- Starting Collar – 6 inch diameter

- Insulated Flexible Duct – 6 inch diameter, 25 feet length

- Register Box (a.k.a. “vent boot”) – 6 in by 10 in

- Register Grille – 6 in by 10 in

- Metal Foil Tape – one roll

- Nylon Zip Ties – 36 inch

Air Duct Installation Tools

The tools needed for this project are:

- Handsaw

- Carpenter’s square

- Tape Measure

- Step Ladder

- Cordless Drill/Driver

- 3 inch Wood Screws

- 1/2 inch self-tapping sheet metal screws

- Flashlight

- Cordless Fluorescent Light (very helpful)

- Rotozip

- Sabre Saw (or Jigsaw)

- 15 amp Heavy Extension Cord

- Hammer

- Small Finishing Nail – 4d (penny) size

- Pencil

Duct Work Installation Guide and Tips

The Duct Work chapter from Heating and Cooling Essentials by Jerry Killinger is an excellent introduction to duct work operation, materials and installation.

How to Install a Ceiling Air Vent

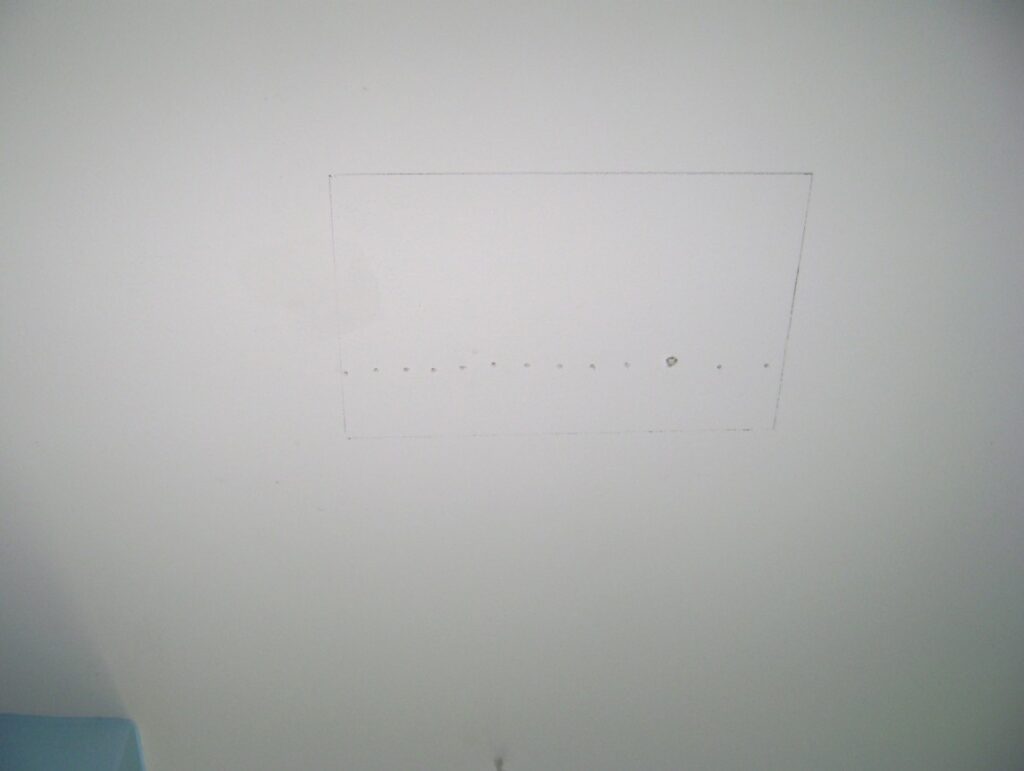

The first task is to locate the new vent boot on the ceiling. I measured the existing ceiling register and plotted the new register in an identical position on the right side of the room. A carpenters square is used to draw a perfect 6″ by 10″ outline on the ceiling where the new hole will be cut for the air vent.

I relied on the regular spacing of the ceiling joists such that the register box would be in the gap between the ceiling joists. Before cutting the drywall, I drove a finishing nail into the ceiling to verify there were no joists, making a series of small holes as shown below. If I made a mistake in the position of the register box, it’s easy to patch the small hole made by a finishing nail. A stud finder could be used.

A Rotozip spiral saw is used to cut the drywall for the ceiling register. Tip: Have a helper hold a vacuum cleaner hose up to the saw to catch most of the dust.

I left the drywall panel in place to prevent the attic insulation from falling into the room. I’ll remove the panel after the insulation is cleared away in the attic.

Now it’s time to go into the attic.

Attic Access for Ductwork

Be extremely careful while working in the attic. Step only on the joists because the drywall under the insulation will not support your body weight – you can fall through the ceiling – resulting in injury or at least a messy drywall repair.

The attic gets very hot in the summer and you can quickly over heat. It’s best to work very early in the morning before it gets hot.

I needed to go into the attic to install the register box and flexible air duct. But I found there was a problem – I couldn’t get to the attic above the bedroom because the roof deck over the main house didn’t leave enough room to squeeze my 215 lb frame through the scuttle hole. Crawling wasn’t an option due to the risk of falling through the ceiling.

To solve the problem, I cut the roof deck with a handsaw and sabre saw as shown in the photo below. This allowed me to crouch and slide through with ample handholds while walking on the ceiling joists.

View of the attic scuttle hole looking back to the main house:

Here’s the insulation problem I found – mounds of it were on the left, but little or no insulation was over the rear areas of the attic above the bedroom. I redistributed the insulation evenly over the attic.

This project is continued in How to Add an Air Duct to a Room – Part 2.

Take care,

Bob Jackson

I have flat roof in the back of my house. How can I insulate it and or add a vent to produce more air. The temperature is much different in this living space.

Hi Cedie, there are options with placing HVAC units on top of the flat roof and adding venting, but it becomes more cumbersome and potentially costly and operationally difficult. You can also consider a minisplit solution, which is ideal for situations like this where ducting is not possible or too challenging.